Ukuphenduka Okukodwa

Lapho uthatha ibhande lokudlulisa ukunyakaza okuphendukayo.ingxenye ye-arc ye-conveyor izohlangana ne-conveyor eqondile futhi iziphetho zombili zesigaba se-arc kufanele ziqondiswe ku-straight, bese umthumeli uzosebenza kahle.

Irediyasi yangaphakathi idinga okungenani izikhathi ezingu-2.2 ububanzi bebhande lokuthutha .

I-STL1 ≧ 1.5 XW noma i-STL1 ≧ 1000mm

Ukuphenduka okukodwa akukhawuli ku-90°;kufanele ithobele umkhawulo wokujika irediyasi futhi yenze umklamo ukusuka ku-15°, 30°, 45°, 60°, 75°, 90°,.... kuya ku-360°.

Ukuphenduka kwe-serial

Lapho uthatha ibhande lokudlulisa ukunyakaza okuphendukayo.ingxenye ye-arc ye-conveyor izohlangana ne-conveyor eqondile futhi iziphetho zombili zesigaba se-arc kufanele ziqondiswe ku-straight, bese umthumeli uzosebenza kahle.Ubude bokusebenza okuqondile budinga izikhathi ezi-2 ububanzi bebhande lokudlulisa.Ngomnyakazo oguqukayo we-serial, sicela ungadizayini ukuphenduka okungaphezulu kuka-4.

Irediyasi yangaphakathi idinga okungenani izikhathi ezingu-2.2 ububanzi bebhande lokuthutha .

I-STL1 ≧ 1.5 XW noma i-STL1 ≧ 1000mm

I-STL2 ≧ 2 XW noma i-STL2 ≧ 1500mm

Amanothi

Lapho isidluliseli sisebenza, kuzoba lula ukwenza imisindo engajwayelekile ngenxa yesimo sokuma nokudlidliza.Ukuphela kokungenzi lutho kwebhande akukwazanga ukunyakaza kuze kube yilapho kuba nokushuba okwanele ukuze kunqobe ukungqubuzana phakathi kwebhande nendlela yokuthwala.Le misindo ingaqedwa ngokusebenzisa igrisi noma uketshezi lwensipho ukuze kugcotshwe ukubamba izinsimbi nezindwangu zokugqoka.

I-HONGSBELT amabhande aphendukayo we-serial, angasetshenziswa endaweni emanzi enezinga lokushisa eliphezulu, njengesitimu esinezinga lokushisa elingu-95°C.Sincoma ukuthi irediyasi yangaphakathi kufanele ibe ngaphezu kuka-3 ububanzi bebhande, futhi i-engeli yokujika okukodwa noma uchungechunge ayikwazi ukuba ngaphezu kuka-180°.Sinemiklamo eminingi yangempela kanye nolwazi lwereferensi yakho;sicela uxhumane nomnyango wethu wamasu noma ama-ejensi endawo.

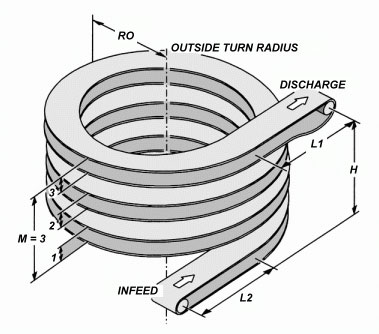

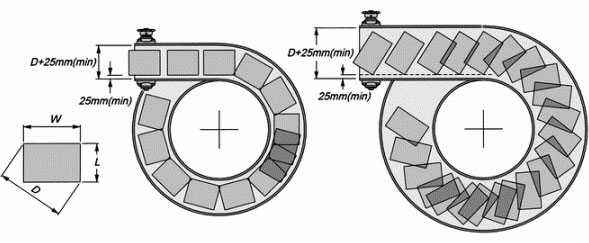

I-Spiral Conveyor

Lapho uhlobo olubuyayo oluyi-spiral conveyor iliphi ibhande elisendleleni ebuyayo elisebenza ngendlela yokuthutha kodwa libheke ohlangothini oluhlukile liklanywe ngokuphenduka okulandelanayo futhi lisetshenziswe ohlangothini olufanayo, lizokwenza umumo njengejiko elizungezayo.Emaphethelweni womabili ama-spiral turnings nawo ayadingeka ukuthi aqondise ekuqondeni, bese esebenza.Ubude obuncane bokuqondile kufanele bube okungenani izikhathi ezingu-1.5 ububanzi bebhande lomthumeli, futhi abukwazanga ukuba bufishane kuno-1000mm.

I-radius yangaphakathi ye-spiral conveyor ijikeleza ngama-degree angu-360 spiral;qaphela inani lezendlalelo ezingadluli ngaphezu kwezingqimba ezi-3, kuphinde kwasho ukuthi i-engeli ephelele ejikelezayo ye-spiral conveyor ayinakudlula ngaphezu kwamadigri angu-1080.

Amanothi e-Spiral Conveyor

Kumabhande aphendukayo e-HONGSBELTserial, uma irediyasi yangaphakathi ingaphezu kuka-2.5 ububanzi bebhande , izokwenza imisindo engajwayelekile ngenxa yesimo sokuma nokudlidliza.Ukuphela kokungenzi lutho kwebhande akukwazanga ukunyakaza kuze kube yilapho kuba nokushuba okwanele ukuze kunqobe ukungqubuzana phakathi kwebhande nendlela yokuthwala.Le misindo ingaqedwa ngokusebenzisa igrisi noma uketshezi lwensipho ukuze kugcotshwe ukubamba izinsimbi nezindwangu zokugqoka.

Ifomula yokubala ye-Outside Radius ye-Spiral Conveyor

Umfanekiso ongezansi uyifomula yokubala yerediyasi yangaphandle/yangaphakathi yesistimu yebhande lokuhambisa elivunguzayo.

IFOMU:

Ubude bebhande lokuthutha = 2B+ (ububanzi be-sprocket x 3.1416)

A = D × 3.1416 × P ( X )

B = ( √ H2 + A2 ) + L1 + L2, B = A / Cos DEG.noma B = H / Tan DEG.

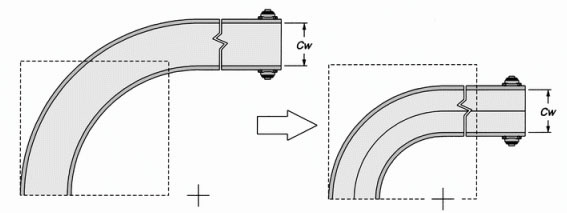

Yehlisa Ngaphakathi Irediyasi

Kunemikhawulo eminingana eqinile engaba ngaphakathi kwerediyasi yamabhande okujika e-HONGSBELT.Lapho uklama futhi ukhiqiza amabhande okuguqula, inkinga yesikhala yefektri izohlangana ngaso sonke isikhathi.Imboni ayikwazi ukuhlalisa umshini wokuthutha omkhulu;kuyadingeka ukunciphisa indawo engaphakathi yebhande.Ingase ithathe imigqa emibili yamabhande noma imigqa eminingi yedizayini yebhande engxenyeni yokujika ukuze imiselele ibhande elilodwa, ukuze inqobe inkinga yobubanzi obudlulele obungaphakathi kwerediyasi.Kodwa-ke, lo mklamo ungase ubangele ukuthi ijubane lebhande langaphandle lihambe kancane kunebhande langaphakathi.Sicela unake ukuthi ingabe lokhu kuzothinta ukusebenza kahle kwesistimu yokuthutha noma cha.

Design Isibonelo

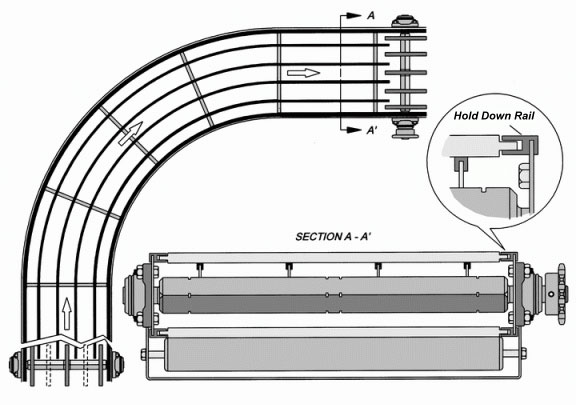

Isibonelo Sokufakwa Kwesitimela Sokubamba Phansi

I-Hold Down Rail yenziwe ngezinto ze-HDPE.Ukufakwa kwe-Hold Down Rail engxenyeni ye-rabbet yomumo ongu-C kufanele kuhambisane nohlaka lwensimbi olusohlangothini lwesidluliseli, kulandele i-radian bese ulifaka, ukuze uqedele ukufaka.Ngendawo yokusebenza kwezinga lokushisa eliphansi, iyatholakala ukuze usebenzise isifudumezi segesi noma isifudumezi somoya sikagesi ukusishisisa sifike ku-100~120℃ bese siyigoba ngendlela efanele ukuze ilingane nokufakwa okudingekayo.

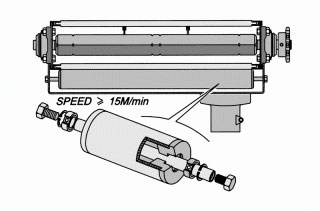

Isivinini sokusebenza

Ibhande lizoba nesimo sokunqwabelanisa ngendlela yokubuyisela, futhi liphumele ekutheni ibhande lime isikhashana futhi lidlidlize.Ngakho-ke, lapho isivinini sokusebenza singaphezu kuka-20M ngomzuzu, sebenzisa amarola anebhola ukuze ashintshe ama-reiling down asesimweni sendlela yokubuya azoxazulula inkinga.

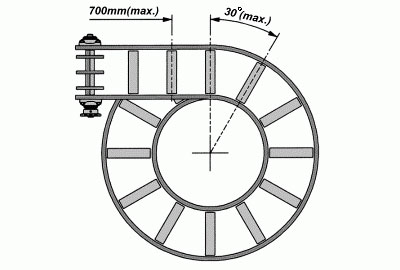

Umkhawulo Wesikhawu we-Return Way Roller

Uma uphendula isistimu yebhande lokudlulisa sebenzisa amarola anamabhola ukusekela indlela ebuyayo, isikhawu phakathi kwamarola esigabeni esiqondile kufanele sibe sincane kuno-650mm.I-engeli efakiwe esigabeni sokujika ayibi ngaphezu kuka-30 degree noma ubude bejika langaphandle abukho ngaphezu kuka-600mm, okuyisilinganiso se-engeli efakiwe.Izoba nendawo yokuxhumana emaphakathi uma amarola endlela yokubuya esekela ibhande.Uma ubude bejika langaphandle bungaphezu kuka-600 mm wesikhawu serola, kufanele ifake umhlahlandlela wesilayidi esisekelayo (UHMW) ukuze kuqinisekiswe ukusebenza ngokuzinza kwendlela ebuyayo.

Amanothi Obubanzi Bebhande

Uma imikhiqizo ilayisha endleleni yokuphethula isistimu yokuthutha, izolandela ukunyakaza kwe-liner ye-conveyor ukuya phambili.Imikhiqizo ayijikelezi phezu kwebhande ngenxa yokuthi ijubane lomugqa lebhande lokuthutha lisendleleni yekhonsathi ngesikhathi sokuthutha.Ngakho-ke, lapho uklama isistimu yebhande lokudlulisa, ububanzi bebhande kufanele bube bukhulu kunobubanzi obukhulu bomkhiqizo wokuthwala.