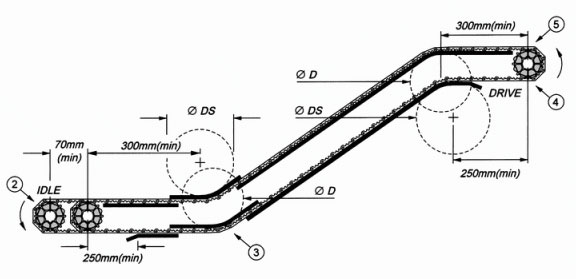

I-Swanneck conveyor

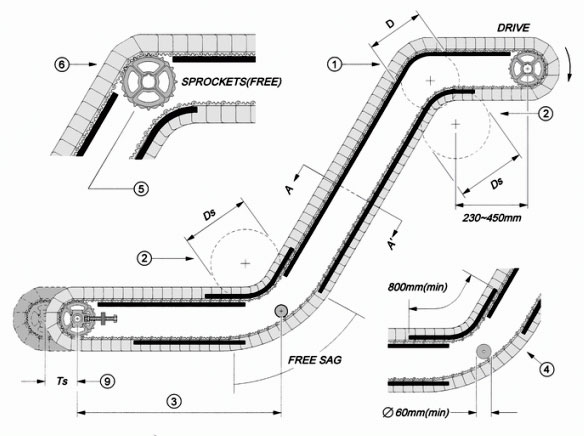

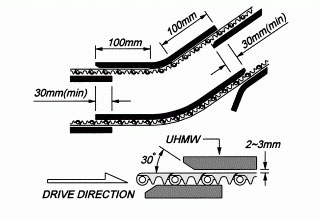

Indlela esekelayo yendawo egobile yesidluliseli esigobileyo iyakwazi ukusebenzisa amapheshana epulasitiki anokungqubuzana okuphansi, njenge-UHMW, HDPE, ne-Acetal, ukuze kube usekelo oluphansi.Ngobubanzi obuncane obugobile, sicela ubhekisele ekucacisweni kweValue D&Ds.

I-backbend radius iyi-tension eqinile;sicela usebenzise amapheshana epulasitiki anokungqubuzana okuphansi, njenge-UHMW, HDPE, ne-Acetal ukuze uyikhiqize.Ngobubanzi obuncane obugobile, sicela ubhekisele ekucacisweni kweValue D&Ds.

Isikhundla sokushayela endleleni yokubuyisela ye-swanneck inclined conveyor iphinde ibe uhlobo lwe-backbend radius;ukushuba okuxekethile.Ingase yakhelwe ngamarola noma amapheshana epulasitiki anokungqubuzana okuphansi ukuze asekele.

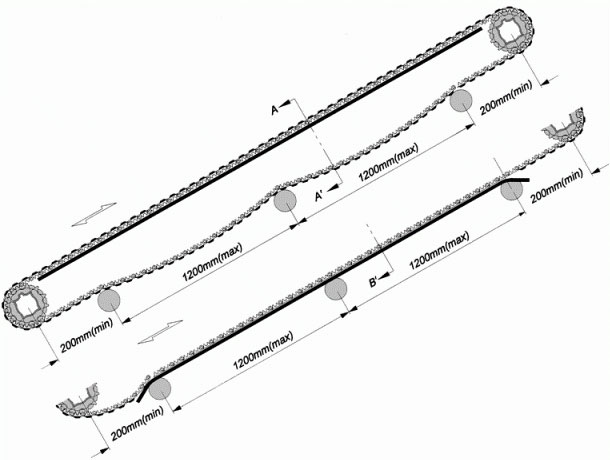

Uma ubude obuvundlile phakathi kwe-sprocket engenzi lutho kanye nendawo egobile ingaphezu kuka-900mm, sicela ufake ama-wearstrip ngaphansi kwendlela ebuyayo.

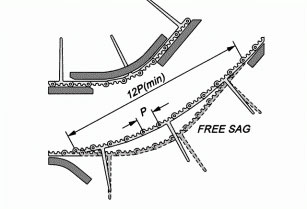

Uma kukhona i-catenary sag evela ku-returnway ye-swanneck inclined conveyor futhi isivinini sokusebenza singeqi ku-20M/min, singashaywa indiva futhi siyiyeke inhle ngokukhululeka.Kodwa-ke, uma isivinini singaphezu kuka-20M/min, kuyadingeka ukusetha irola enobubanzi obungaphezulu kuka-60mm ukuze unciphise ukwenzeka kokugxuma okubangelwe yi-catenary sag yebhande lokuhambisa.

Lapho wamukela i-Hongsbelt drive sprocket ukuthi ibe indlela esekelayo ye-engeli egobile futhi isivinini sokusebenza singaphezu kuka-15m/min, kufanele isetshenziswe i-sprocket enamazinyo angaphezu kwangu-12, kodwa sicela ulungise wonke ama-sprocket anamasongo agcinayo futhi ususe ipuleti eliqondisayo i-sprocket.

Kuyadingeka ukuklama ngama-roller acindezelwe noma ama-strips ku-conveyor ethambekele ye-swanneck.Iphimbo elihambisanayo lamapheshana akumele libe ngaphansi kuka-100mm futhi kufanele limise isilungisi se-tension endaweni yokungenzi lutho ukuze sithole ukungezwani okufanele.

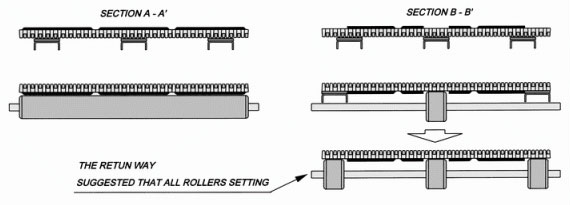

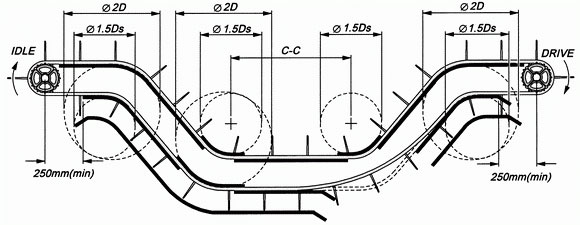

Isigaba A-A' Ukucaciswa Kwedizayini

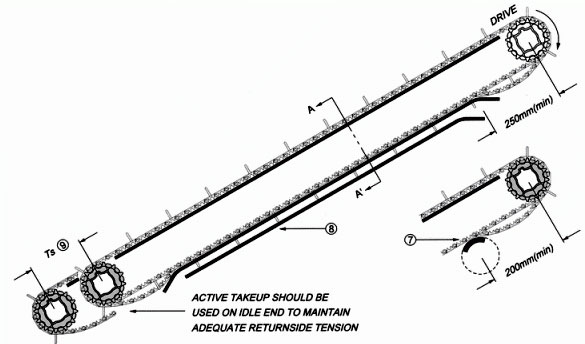

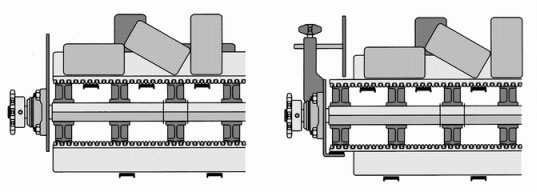

I-Conveyor Ehlanganisiwe

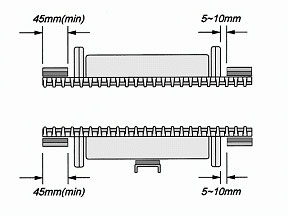

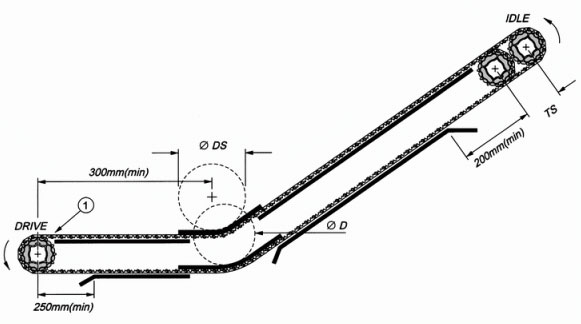

Uma indlela yokushayela ye-conveyor ethambekele kuyidrayivu ephezulu, indawo yokuxhumana phakathi kwe-drive sprocket center kanye ne-roller yokuqala noma i-wearstrip ngendlela ebuyayo kufanele igcine isikhawu singaphezu kuka-200mm ukuze ibhande libe nokunyakaza kwesikhala esanele futhi ligweme ukuthi libe nokusebenzelana okungajwayelekile nama-sprockets. futhi kubangele isimo esiminyene.Sicela ubheke isikhundla sesi-7 somfanekiso ongenhla.

Uma ububanzi bebhande bungaphezu kuka-600mm, kufanele kufakwe imichilo ephakathi nendawo phezulu kwendiza ngendlela ebuyayo.Sicela ubhekisele kuSigaba A - A' futhi ubone isikhundla 8 somfanekiso ongenhla.

I-TS ukulungiswa kwengcindezi;ukuze uthole ukulawulwa kokulungisa izikhala, sicela ubheke isahluko se-Belt Length & Tension.Sicela ubheke isikhundla 9 somfanekiso ongenhla.

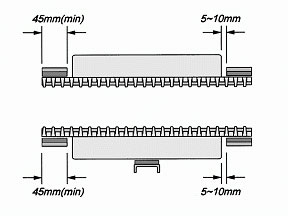

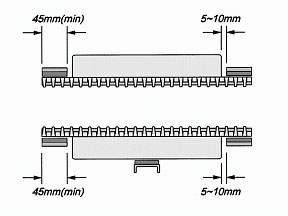

Isigaba A-A' Ukucaciswa Kwedizayini

Thayipha i-EL

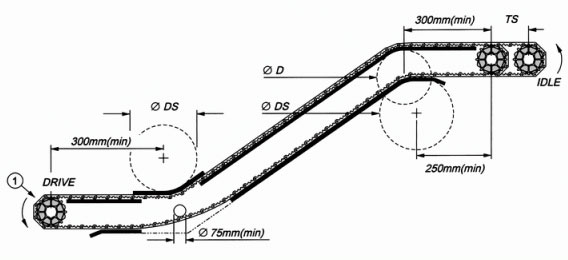

Isikhala phakathi kwe-drive/idler sprocket kanye nephoyinti lokuxhumana lokuqala ngendlela yokubuyisela, kungakhathaliseki ukuthi i-roller noma i-wearstrip iyini, kufanele igcinwe ngaphezu kuka-200mm.

Ibanga eliwumkhawulo phakathi kwawo wonke ama-roller asekelayo ngendlela yokubuyisela alikho ngaphezu kuka-1.2M.

Ukuze uthole amanye amaphuzu okuklama, sicela ubheke ku-Swanneck Conveyor kanye nomfanekiso ongezansi.

Ku-Series 200 EL kanye no-Series 300HDEL, acutshungulwa futhi anamathiselwa izingcezu ze-TPE ebhandeni le-PP.I-TPE iyimpahla esezingeni eliphezulu evimbela ukushushuluza;isicelo esivame kakhulu isibambo se-skidproof sezixubho.Ingaphinda isetshenziswe ngaphandle kokungabaza mayelana nokuvikelwa kwemvelo, futhi ixube nezinto ze-PP ukuze ibe isithasiselo esingaqinisa ukuqina.Kungakhathaliseki ukuthi ihlehla noma yehla, i-engeli yokuthambekela ayikwazi ukudlula u-40°.

Ukucaciswa Kwedizayini Yesigaba

Ubuncane be-diameter ye-roller yendlela yokubuya ayikwazi ukuba ngaphansi kuka-600mm.Ingasebenzisa ama-roller ngendlela yokubuyisela kulo lonke uhambo;Nokho, isivinini kufanele sibe phakathi kuka-30M/min futhi i-catenary sag kufanele ilawulwe ngaphakathi kuka-35mm ukuze kugwenywe amarola e-TPE flange ashayayo ane-engeli enkulu futhi aphumele ekusebenzeni kabi.

Ingase futhi isebenzise indlela yokuklama njengoba umfanekiso, isigaba B-B', ubonisa ngenhla.Emfanekisweni ongenhla, izindwangu ezigqokwayo zisekelwa nhlangothi zombili kanye nerola esekelwe phakathi nendawo.Emfanekisweni ongezansi, yamukele amarola ukuze asekele ezingxenyeni ezintathu.Zombili ziyindlela engcono kakhulu yokuklama.

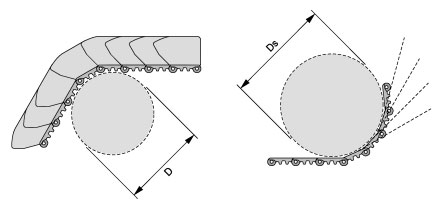

I-Backbend Radius DS

Wonke amabhande okuthutha e-HONGSBELT imikhiqizo ye-serial yahlanganiswa yaba iyunithi ekhiyiwe, inomkhawulo omncane wokubuyisela emuva werediyasi;ngakho-ke, ukwenza ibhande lidlule endaweni engemuva ngokushelela, sicela unake umkhawulo wobubanzi obuncane lapho uklama isidluliseli bese ubhekisela kuthebula elingezansi ukuze ulungise i-radius yochungechunge ngalunye ).

Ibhande le-HONGSBELT lokuhambisa liyakwazi ukusebenza ngomklamo wokudlulisa othambekele;ngokuyisisekelo iyatholakala ukuze ifinyelele noma iyiphi i-engeli ethambekele ngokubala okulungile kobubanzi berediyasi ye-backbend.

iyunithi: mm

| Uchungechunge | 100 A | 100 B | 200 A | 200 B | 300 | 400 | 500 | 501B | 502A/B | |

| D | Ngaphandle kweSide Guard | 250 | 250 | 135 | 120 | 200 | 45 | 150 | 150 | 180 |

| With Side Guard | 250 | 250 | 135 | 120 | 200 | - - | - - | 180 | 200 | |

| DS | Ngaphandle kweSide Guard | 250 | 200 | 150 | 120 | 220 | 45 | 150 | 180 | 200 |

| With Side Guard | 280 | 230 | 300 | 290 | - - | - - | - - | 200 | 230 | |

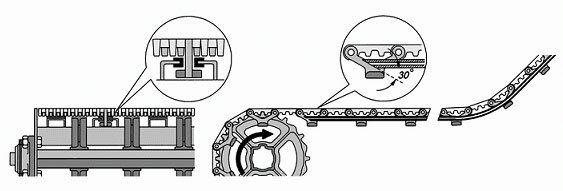

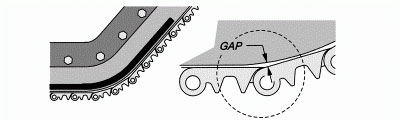

Backend Radius Bamba Phansi Incazelo

I-backend radius yesistimu yokuthutha ethambekele iwumklamo ovame kakhulu wokufeza inhloso yokudlulisa ethambekele.Ngakho-ke, kuyadingeka ukucabangela ukunyakaza okubushelelezi kwendawo yebhande noma phansi lapho uklama indawo yokubamba phansi.Sicela ubhekisele emfanekisweni ongenhla.Mayelana nempahla efanele yokuxhumana nokugqoka ngebhande, sincoma ukuthi usebenzise i-HDPE noma i-UHNW impahla uma ijubane lingaphansi kuka-20 M/min;uma ijubane lingaphezu kuka-20 M/min, sicela usebenzise i-UHMW noma impahla ye-TEFLON.

Sicela ucubungule noma ugaye indawo yokubamba phansi ibe ngu-30 degree chamfer emnyango ukuze uqinisekise isihambisi ngokunyakaza okushelelayo.

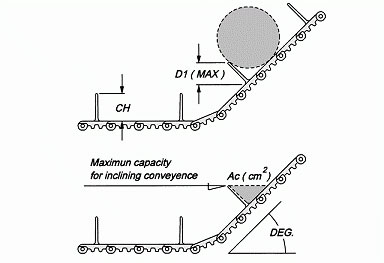

I-engeli namandla

Uma umthamo wokuthutha impahla mkhulu kakhulu, ukuze kugwenywe ama-athikili ukuwa enqubweni yokuthutha, akufaneleki ukuthatha onogada abasemaceleni abaphansi noma idizayini ene-gradient engumqansa kusihambisi esithambekele.Sicela unake ngokukhethekile ubudlelwano obuhlobene phakathi komthamo wezimpahla kanye ne-engeli ehlehlayo, futhi ubhekisele emfanekisweni ongezansi.

Iyunithi : CH=mm, D1= mm, Ac=cm2

| DEG. | 15° | 20° | 25° | 30° | 35° | 40° | 45° | 50° | ||

| CH | 25 | D1 | 23 | 22 | 21 | 20 | 19 | 17 | 16 | 15 |

| Ac | 11 | 8 | 6 | 5 | 4 | 3 | 3 | 2 | ||

| 50 | D1 | 46 | 45 | 46 | 40 | 38 | 35 | 32 | 29 | |

| Ac | 46 | 34 | 26 | 21 | 17 | 14 | 12 | 10 | ||

| 75 | D1 | 70 | 67 | 64 | 61 | 57 | 53 | 48 | 42 | |

| Ac | 104 | 77 | 60 | 48 | 40 | 33 | 27 | 23 | ||

| 100 | D1 | 9. | 90 | 86 | 81 | 76 | 70 | 64 | 57 | |

| Ac | 186 | 137 | 107 | 86 | 71 | 60 | 50 | 41 | ||

| 125 | D1 | 117 | 113 | 108 | 102 | 95 | 88 | 80 | 71 | |

| Ac | 291 | 214 | 167 | 136 | 111 | 92 | 77 | 65 | ||

| 150 | D1 | 140 | 136 | 129 | 122 | 114 | 106 | 96 | 86 | |

| Ac | 490 | 360 | 281 | 227 | 186 | 156 | 130 | 109 | ||

Ngomphumela wokulayisha umthamo, sicela uphindaphinde inani le-Ac ngobubanzi obusebenzayo (cm) bendiza .

Yenqaba I-Conveyor

Ngokuvamile, ngomklamo wokwehla kwesistimu yokuthutha, sincome ukusebenzisa uhlobo A noma uhlobo B njengesibonelo sokuthutha.uhlelo lokuthutha ludizayinelwe ukushayela ngezansi kwesithuthi njengoba kukhombisa indawo 1 yomfanekiso ongezansi.Ukuze uthole inani le-D & DS, sicela ubhekisele ku-Backend Radius Ds kumenyu engakwesokunxele.

Uhlobo B

Uma kudingekile ukusebenzisa uhlobo C njengesibonelo somklamo wokuthutha, izikhala zokulungisa u-T kufanele zigcinwe okungenani zibe ngu-75mm.Ukuze uthole inani le-D & DS, sicela ubhekisele ku-Backend Radius Ds kumenyu engakwesokunxele.

Uhlobo C

Ukungezwani okufanele kwesikhundla 3 kufanele kutholwe ekulungiseni ukungezwani kwesikhundla 2.

Ukuze wenze i-backend radius ibe sesimweni sesi-4 kanye naphansi kwe-drive sprocket ukuze uthole i-engeli ehambisanayo engcono kakhulu kanye nokungezwani okufanele, futhi kuzuze ukusebenza kwebhande, kuyadingeka ukulungisa ukungezwani endaweni yesi-2 futhi ubambe phansi endaweni yesi-3.

Uma ingakwazi ukwamukela ukushuba kwesimo esifanele endaweni yesi-2, kuzophumela ekutheni ibambe phansi ingakwazanga ukuyithola endaweni yesi-3 neyesi-4. Lokho kungase kubangele ukwenzeka kokugingqana kwesikhala sebhande okungaholela ku-engeli egoqayo endaweni yesi-5. I-sprocket izoba nokuzibandakanya okungalungile futhi kuphumele ekumiseni nasekuhlulekeni.

Uhlobo D

Multi Backend Radius

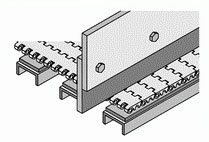

Ngedizayini ye-backend radius, imichilo yokugqoka kufanele ibekwe endleleni ebuyayo ukuze isekele indawo engaphezulu yendiza, ukuze kugwenywe ukonakala kwebhande noma ukugoqa ifomu lohlaka lokudlulisa.Sicela ubheke umfanekiso ongezansi.

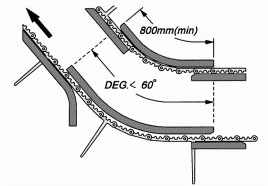

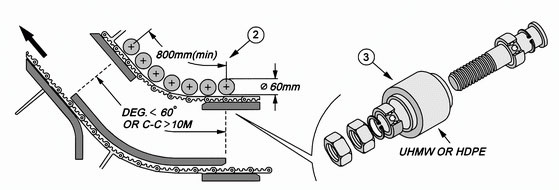

Uma i-engeli yokugoba ingaphansi kwamadigri angu-60, ingasebenzisa isitimela sokubamba phansi esenziwe ngepulasitiki yobunjiniyela be-UHMW ukuze ibambe izinhlangothi zombili zokuphela kwebhande elingemuva.Ukuze uthole inkomba yenani le-D & DS sicela ubheke ithebula elilandelayo ekupheleni kwaleli khasi ngezansi.)

Uma i-engeli ehlehlayo ingaphezu kuka-60 degree, sincoma ukuthi usebenzise i-roller eshayelwayo ukuze umise ngaphansi kwebhande, ukuze wehlise indawo yokuhuzuka futhi unciphise ukushuba kwendlela yokubuya.

Isitayela esinesitayela sokubamba phansi irola kufanele yakheke ngokucutshungulwa okunembayo, kufanele iqine ingagxili ku-engeli yensimbi yozimele wokuthutha ngokusekela ngesikulufu njengoba kuboniswe ngenhla.(Ukuze uthole inkomba yenani le-D & DS sicela ubheke ithebula elilandelayo ekupheleni kwaleli khasi ngezansi.)

Ibanga lendlela yokubuyisela i-catenary sag iyanconywa ukuthi wonge okungenani ububanzi bemojula eyizicucu ezingu-12, ukuze wenze indlela yokubuya ibe nesikhala esanele sokukhulula ukungezwani.

Amanothi

Ibhande le-HONGSBELT le-modular lifaneleka kakhulu ukusebenzisa kuzo zonke izinhlobo zemvelo yokushisa okuphezulu, njenge-steam namanzi ashisayo acwiliswe emanzini njll. i-backend radius.Sinolwazi oluningi ekusetshenzisweni kwezinga lokushisa eliphezulu, futhi sizimisele ukukusiza.Ngamaphuzu ahlobene okuklama isistimu yokuthutha, ungaxoxisana nathi ngaso sonke isikhathi.

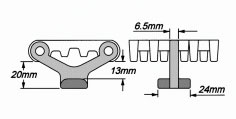

Bamba Phansi Amamojula

I-Incline conveyor ingamisa okwesikhashana amamojula okubambela phansi (i-HDM), iyithuluzi eliqondisayo elakhelwe ngokukhethekile irediyasi engemuva endleleni ebuyayo yesidluliseli.Amamojula okubambela phansi akumklamo omise okwe-T, futhi afakwe ngaphansi kwebhande, ukuze ubambe ibhande.Ingafinyelela umphumela wokuthamba ngaphandle kokubamba phansi indawo ye-backend radius, futhi ungawasebenzisi amarola ukuze asekele ibhande endleleni yokubuya.

Incazelo yokufakwa kwe-HDM

Lapho ufaka i-HDM, sicela usebenzise okokusebenza kwe-coefficient ephansi njenge-UHMW noma i-HDPE endaweni yokuxhumana.Ungavumeli ukuthi i-HDM ixhumane nezinto zensimbi ngokuqondile.Ingase ilimaze ibhande lokuthutha ngenxa yokungqubuzana.Ukuze , Kucutshungulwa i-wearstrip emnyango ku-chamfer engu-30 degree ukuze uthole ukusebenza okungcono kwe-HDM.Sicela ubheke umfanekiso ongenhla.

Side Prevention

Ibhande le-HONGSBELT le-modular conveyor lingakwazi futhi ukunamathisela ngonogada baseceleni abangaguquki ukuvimbela ukuthi imikhiqizo iwele onqenqemeni lwebhande.Impahla yepulasitiki yobunjiniyela obuminyaniswe kakhulu kufanele isetshenziselwe ukwakha okunamathiselwe konogada abaseceleni, futhi kufanele igcine isikhala sokuphepha phakathi kwebhande nonogada oseceleni bohlobo olungaguquki.Ngaphezu kwalokho, kuyadingeka ukugwema ukusebenzisa izinto ezithambile ezifana ne-PVC, i-PU noma i-fiber weaving ukuze uhlikihle endaweni yebhande ngokuqondile, kungase kubangele umonakalo endaweni yebhande.Sicela ubheke umfanekiso ongezansi.

Umkhiqizo Omkhulu Nongangcolisi

Uhlelo lokusebenza olungenhla ngokuvamile alukho ukungcola noma ukuhanjiswa kwemikhiqizo yosayizi abakhulu.Lesi sibonelo sokuklama sinwetshiwe isakhiwo esiyinhloko se-conveyor ngokuqondile, ukwenza umsebenzi njengabaqaphi abaseceleni.

Amanothi Egebe Lokugoqa Ibhande

Isakhiwo semikhiqizo ye-HONGSBELT iyiyunithi ehlanganisiwe ehlanganisiwe.Ngakho-ke, kungakhathaliseki ukuthi ukuvimbela ohlangothini kuqinile kangakanani, igebe elingunxantathu lisazovela endaweni yokugoba yebhande.Sicela ubheke umfanekiso ongenhla.Kufanele kuqashelwe ngesikhathi sokuklama noma kucatshangelwe ukwamukela izesekeli ze-HONGSBELT, onogada baseceleni.Ngaphezu kwalokho, into efana ne-HDPE noma i-UHMW warp, isikhwama sepulasitiki, insalela yempahla yepulasitiki noma enye into eyisicaba kanye nencanyana ingase ingene esikhaleni sebhande noma esikhaleni.

Lezi zinto zangaphandle zingase zidale isidluliseli ukuthi ziminyanise izimo noma ziphazamise ukuzungezisa kwebhande, uma kungenangqondo ukunamathisela nge-HONGSBELT side guard for side side prevention, siphakamisa ukuthi ubukhulu obuncane bezimpahla ezidlulisayo kumele okungenani buphindwe kabili ubukhulu kunegebe elingunxantathu webhande.

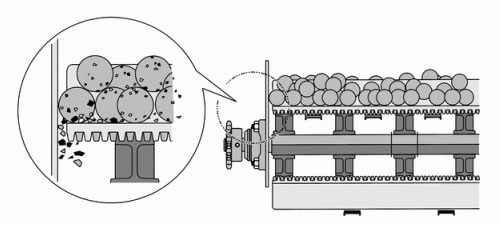

Izinhlayiya Ezincane

Izinto ezincane kanye nezinto ezingcolisa kalula njengamabhisikidi, izithelo ezomile, nefolishi kulula kakhulu ukuwa ukusuka phezulu kwebhande.Izinhlayiya ezincane zalezi zinto zizonqwabelana esakhiweni sokuthutha, bese ziwela ku-chink yebhande lokuthutha.Ukuze uvimbele ukuthi into encane ingene ebhandeni nakwisakhiwo sokuthutha, sincoma ukuthi udizayine isidluliseli sakho njengoba kubonisiwe ngezansi;izothola ukuvikeleka okungcono kwemishini.