Amanothi e-Catenary Sag

Uma ibhande ligijima, kubaluleke kakhulu ukugcina ukungezwani okufanele, ubude obufanele bebhande, futhi akukho nokukodwa kokubandakanyeka okungekho phakathi kwebhande nama-sprockets.Uma isidluliseli sisebenza, ubude obengeziwe buzomuncwa i-catenary sag ngendlela ebuyayo ukuze kugcinwe ukushuba okufanelekile kokudonsa kwebhande.

Uma ibhande lokudlulisa linobude obedlulele endleleni ebuyayo, idrayivu/Idler sprocket izoba nokusebenzelana okulahlekile nebhande, futhi kuphumele ekutheni ama-sprockets aphule ithrekhi noma ama-rails kusihambisi.Ngokuphambene nalokho, uma ibhande liqina futhi lifushane, ukudonsa ukudonsa kuzokwanda, lokhu kucindezeleka okunamandla kuzodala indlela yokuthwala ibhande esimweni sokubuyisela emuva noma i-motor ingaphezu kokulayisha ngesikhathi sokusebenza.Ukungqubuzana okubangelwa ukuqiniswa kwamandla ebhande kungase kunciphise ukuphila kwebhande lokuthutha.

Ngenxa yesimo somzimba sokunwetshwa kokushisa okubalulekile kanye nokufinyela ekushintsheni kwezinga lokushisa, kuyadingeka ukwandisa noma ukwehlisa ubude be-catenary sag ngendlela yokubuyisela.Kodwa-ke, akuvamile ukuthola ubukhulu be-catenary sag ngokubala ubukhulu obunembile phakathi kwezindawo zokuhlanganisa kanye nobukhulu bangempela obudingekayo ama-sprockets ngesikhathi sokuzibandakanya.Ihlala inganakwa ngesikhathi sokuklama.

Sibala izibonelo ezithile zolwazi olusebenzayo ngokuhlaziywa kwezinombolo okunembile kwereferensi yabasebenzisi ngaphambi kokusebenzisa imikhiqizo yomkhiqizo ye-HOGNSBELT.Ukuze ulungise ingcindezi efanele, sicela ubheke Ukulungiswa Kwe-Tension kanye ne-Catenary Sag Table kulesi sahluko.

I-General Conveyance

Sekukonke, sibize isidluliseli ukuthi yibuphi ubude obungaphansi kuka-2M omfishane we-conveyor.Ukuze kuklanywe ukudluliswa kwebanga elifushane, akudingekile ukufaka ama-wearstrip endleleni yokubuya.Kodwa ubude be-catenary sag kufanele bulawuleke ngaphakathi kwe-100mm.

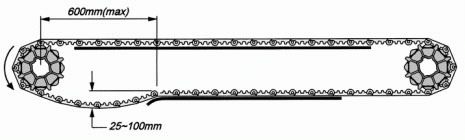

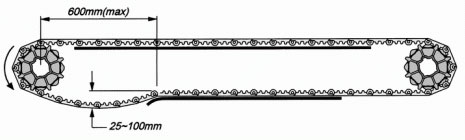

Uma ingqikithi yobude besistimu yokuthutha ingekho ngaphezu kuka-3.5M, ibanga elincane phakathi kwe-sprocket yedrayivu kanye ne-wearstrip yendlela ebuyayo kufanele ilawulwe ngaphakathi kuka-600mm.

Uma ingqikithi yobude besistimu yokuthutha ingaphezu kuka-3.5M, ibanga eliphakeme phakathi kwe-sprocket yedrayivu kanye ne-returnway wearstrip kufanele ilawulwe ngaphakathi kuka-1000mm.

I-Medium and Long Distance Conveyor

Ubude be-conveyor bungaphezu kuka-20M, futhi ijubane lingaphansi kuka-12m/min.

Ubude be-conveyor bufushane kuno-18m, futhi ijubane lifika ku-40m/min.

I-Bidirectional Conveyor

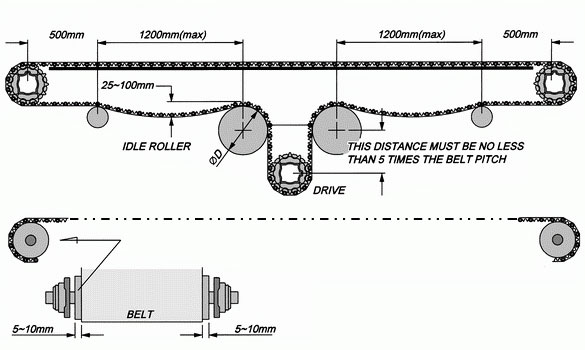

Umfanekiso ongenhla uyisidluliseli se-bidirectional esinomklamo wemoto eyodwa, indlela yokuthwala kanye nendlela yokubuya zombili zaklanywa ngokusekelwa kwama-wearstrips.

Umfanekiso ongenhla uyisihambisi se-bidirectional esinomklamo wamamotho amabili.Ngebhuleki le-synchronizer kanye nedivayisi ye-clutch brake, sicela uthintane nesitolo sezingxenyekazi zekhompuyutha ukuze uthole imininingwane eyengeziwe.

I-Center Drive

Ukuze ugweme ukuthatha ama-axiliary bearings ezingxenyeni ezingenzi lutho nhlangothi zombili.

Ubuncane bobubanzi be-Idler Roller - D ( Indlela Yokubuya)

Iyunithi: mm

| Uchungechunge | 100 | 200 | 300 | 400 | 500 |

| D (imizuzu) | 180 | 150 | 180 | 60 | 150 |

Amanothi Okulungisa Ukushuba

Isivinini sokusebenza sebhande lokudlulisa ngokuvamile sidinga ukuhambisana nenhloso yokudlulisa ehlukile.Ibhande lokuthutha le-HONGSEBLT lifanele isivinini esihlukile sokusebenza, sicela unake ingxenye ephakathi kwejubane lebhande nobude be-catenary sag ngenkathi usebenzisa ibhande le-HONGSEBLT lokuhambisa.Umsebenzi owodwa oyinhloko we-catenary sag ngendlela yokubuyisela ukuhlanganisa ukukhuphuka noma ukwehla kobude bebhande.Kuyadingeka ukulawula ubude be-catenary sag ebangeni elifanele, ukugcina ukungezwani okwanele kwebhande ngemuva kokuzibandakanya nama-sprockets we-drive shaft.Liyiphuzu elibaluleke kakhulu ekwakhiweni okuphelele.Ukuze uthole ubukhulu obufanele bebhande, sicela ubheke Ithebula Le-Catenary Sag kanye nokubalwa kobude kulesi sahluko.

Ukulungiswa Kwengcindezi

Ngokuqondene nenhloso yokuthola ukungezwani okufanele kwebhande lokuthutha.ngokuyisisekelo i-conveyor ayidingi ukufaka idivayisi ehambisana ne-tension kufreyimu yokuthutha, kufanele ikhulise noma inciphise ubude bebhande, kodwa idinga isikhathi esiningi sokusebenza ukuze ithole ukungezwani okufanele kuyo.Ngakho-ke, ukufaka ukulungiswa kwe-tension ku-drive/driven wheel of the conveyor kuyindlela elula yokuthola ukushuba okuhle nokufanelekile.

Ukulungiswa Kwesitayela Sesikulufa

Ngesizathu sokuthola ukungezwani kwebhande elifanele kanye nokusebenza kahle.Ukuthathwa kwesitayela se-screw kushintsha indawo yeshifu eyodwa, ngokuvamile engenzi lutho, ngokusebenzisa izikulufu zomshini ezilungisekayo.Ama-shaft bearings abekwe ezindaweni ezivundlile kuhlaka lokuthutha.Ukuthatha isitayela sesikulufu kusetshenziselwa ukuhambisa shaft ngobude, ngaleyo ndlela kuguqule ubude besithumeli.Ibanga elincane phakathi kwendawo yokungenzi lutho kufanele ligcine okungenani ububanzi obungu-1.3% bobude befreyimu ye-conveyor, futhi bungabi ngaphansi kuka-45mm.

Amanothi Okuqalisa Kwezinga Lokushisa Eliphansi

Uma ibhande le-HONGSBELT lisetshenziswa esimweni sokushisa esiphansi, kufanele kuqashelwe ngenxa yesimo sokuqandisa ebhandeni ngesikhathi sokuqalisa.Kungenxa yokuthi amanzi asele asala ngemva kokugeza noma ukuvala okokugcina, azoqina kuyilapho izinga lokushisa eliphansi libuyela ezingeni lokushisa elivamile futhi ukuma okuhlangene kwebhande kuzobanda;lokho kuzovala isistimu yokuthutha.

Ukuze uvimbele lesi simo ngesikhathi sokusebenza, kubalulekile ukuqala isithuthi sisesimweni sokusebenza kuqala, bese uqala izifeni zefriji ukomisa amanzi asele kancane kancane, ukuze kugcinwe indawo yokuhlangana isesimweni esisebenzayo.Le nqubo ingagwema ukwephula isidluliseli ngenxa yokushuba okunamandla okubangwa ngenxa yokuthi amanzi asele endaweni yokuhlangana kwebhande abe yiqhwa.

I-Gravity Style Take-Up Roller

Esimeni sokusebenza sokushisa esiphansi, ama-rails asekelayo angase akhubazeke ngenxa yokufinyela ngaphansi kwezinga lokushisa elibanda kakhulu, futhi indawo yokuhlanganisa yebhande izoba yiqhwa, futhi.Lokho kuzodala ukuthi ibhande lokuthutha lisebenze nesimo sokungenisa esihlukile ekusebenzeni ezingeni lokushisa elijwayelekile.Ngakho-ke, sincoma ukufaka i-roller yokuthatha amandla adonsela phansi ebhandeni ngendlela yokubuyisela;ingagcina ukungezwani okufanele kwebhande kanye nokuzibandakanya okufanele kwama-sprockets.Akudingekile ukufaka i-roller yokuthatha amandla adonsela phansi endaweni ethile;noma kunjalo, ukuyifaka njengevaliwe njengoba i-drive shaft izothola umphumela ophumelela kakhulu.

I-Gravity Style Take-up

Ukuthathwa kwesitayela se-gravity kungasebenza ngaphansi kwezimo ezilandelayo:

Ukwehluka kwezinga lokushisa ngaphezu kuka-25°C.

Ubude befreyimu ye-conveyor yinde kuno-23M.

Ubude befreyimu ye-conveyor ingaphansi kuka-15 M, futhi isivinini singaphezu kuka-28M/min.

Isivinini sokusebenza ngezikhathi ezithile singu-15M/min, futhi isilinganiso sokulayisha singaphezu kuka-115 kg/M2.

Isibonelo se-Gravity Style Take-Up Roller

Kunezindlela ezimbili zokulungiswa kwe-tension for gravity style take-up roller;enye iwuhlobo lwe-catenary sag kanti enye iwuhlobo lwe-cantilever.Sincoma ukuthi usebenzise uhlobo lwe-catenary sag endaweni yokushisa ephansi;uma isivinini sokusebenza singaphezu kuka-28M/min, singakuncoma ukuthi usebenzise uhlobo lwe-cantilever.

Ngesisindo esijwayelekile serola yokuthatha isitayela se-gravity, izinga lokushisa elivamile elingaphezu kuka-5°C kufanele libe ngu-35 Kg/m futhi elingaphansi kuka-5 °C kufanele libe ngu-45 Kg/m.

Mayelana nemithetho yobubanzi berola yokuthatha isitayela se-gravity, uchungechunge 100 nochungechunge 300 kufanele lube ngaphezu kuka-200mm, kanti uchungechunge 200 kufanele lube ngaphezu kuka-150mm.

I-Length Conveyor

IFOMU:

LS=LS1+LS1 XK

LS1=LB+L/RP X LE

LB=2L+3.1416X(PD+PI)/2

| Uphawu | Ukucaciswa | Iyunithi |

| K | I-coefficient yokwehluka kwezinga lokushisa | mm / m |

| L | Ubude bozimele besithumeli | mm |

| LB | Ubude bethiyori bebhande lokuthutha | mm |

| LE | Ukushintsha kwe-catenary sag | mm |

| I-LS1 | Ubude bebhande ezingeni lokushisa elivamile | mm |

| LS | Ubude bebhande ngemva kokushintsha kwezinga lokushisa | mm |

| PD | Ububanzi be-sprocket yedrayivu | mm |

| PI | Ububanzi be-idler sprocket | mm |

| RP | I-return way roller pitch | mm |

Ngevelu ye-LE & RP, sicela ubheke Ithebula le-Catenary Sag kumenyu engakwesokunxele.

Ithebula Le-Coefficient Yokuhlukahluka Kwezinga lokushisa - K

| Izinga Lokushisa | I-Coefficient yobude ( K ) | ||

| PP | I-PE | I-Actel | |

| 0 ~ 20 °C | 0.003 | 0.005 | 0.002 |

| 21 ~ 40 °C | 0.005 | 0.01 | 0.003 |

| 41 ~ 60 °C | 0.008 | 0.014 | 0.005 |

Incazelo Yenani

Isibonelo 1:

Ubude befreyimu ye-conveyor buyi-9000mm;yamukela i-Series 100BFE ububanzi obungu-800mm, isikhala se-roller yendlela yokubuya ngu-950mm, ama-sprocket okushayela/angenzi lutho akhethiwe ukuze athathe uchungechunge lwe-SPK12FC okuyi-diameter engu-192mm, isivinini sokugijima ngu-15m/min, kanti izinga lokushisa elisebenzayo lisuka ku- -20 °C kuya ku-20°C.Umphumela wokubala wokulinganisa wokufaka umi kanje:

LB=2×9000+3.1416×(192+192)/2=18603(mm)

LS1=18603+9000/900×14=18743

LS=18743+(18743×0.01)=18930 ( Ubukhulu buyanda lapho kusifinyezwa)

Umphumela wokubala ungu-18930mm wokufakwa kwangempela

Isibonelo sesi-2:

Ubude befreyimu yokuthutha buyi-7500mm;yamukela i-Series 100AFP ububanzi obungu-600mm, isikhala se-roller yendlela yokubuya ngu-950mm, ama-sprocket okushayela/angenzi lutho akhethiwe ukuze athathe i-SPK8FC okuyi-diameter engu-128mm, isivinini sokugijima ngu-20M/min, kanti izinga lokushisa elisebenzayo lisuka ku-20°C ukuya ku-20°C. 65°C.Umphumela wokubala wokulinganisa wokufaka umi kanje:

LB=2×7500+3.1416×(128+128)/2=15402(mm)

LS1=15402+7500/900×14=15519

LS=15519-( 15519 × 0.008 )=15395 ( nciphisa ubude bebhande uma kushisa ukunwetshwa)

Umphumela wokubala ungu-15395mm wokufakwa kwangempela.

Ithebula le-Catenary Sag

| Ubude be-Conveyor | Isivinini (m/min) | I-RP ( mm) | I-SAG enkulu (mm) | Izinga lokushisa le-Ambient (°C) | ||||

| Sag | LE | PP | I-PE | ACTEL | ||||

| 2 ~ 4 m | 1 ~ 5 | 1350 | ± 25 | 150 | 30 | 1 ~ 100 | - 60 ~ 70 | - 40 ~ 90 |

| 5 ~ 10 | 1200 | 125 | 30 | 1 ~ 100 | - 60 ~ 70 | - 40 ~ 90 | ||

| 10 ~ 20 | 1000 | 100 | 20 | 1 ~90 | - 50 ~ 60 | 20 ~ 90 | ||

| 20 ~ 30 | 800 | 50 | 7 | 1 ~90 | - 20 ~ 30 | - 10 ~ 70 | ||

| 30 ~ 40 | 700 | 25 | 2 | 1 ~ 70 | 1 ~ 70 | 1 ~90 | ||

| 4 ~ 10 m | 1 ~ 5 | 1200 | 150 | 44 | 1 ~ 100 | - 60 ~ 70 | - 40 ~ 90 | |

| 5 ~ 10 | 1150 | 120 | 28 | 1 ~ 100 | - 60 ~ 60 | - 30 ~ 70 | ||

| 10 ~ 20 | 950 | 80 | 14 | 1 ku85 | - 40 ~ 40 | - 10 ~ 50 | ||

| 20 ~ 30 | 800 | 60 | 9 | 1 ~65 | - 10 ~ 30 | 1 ~80 | ||

| 30 ~ 40 | 650 | 25 | 2 | 1 ~ 40 | 1 ~ 60 | 1 ~80 | ||

| 10 ~ 18 m | 1 ~ 5 | 1000 | 150 | 44 | 1 ~ 100 | - 50 ~ 60 | - 40 ~ 90 | |

| 5 ~ 10 | 950 | 120 | 38 | 1 ~ 100 | - 50 ~ 50 | - 40 ~ 90 | ||

| 10 ~ 20 | 900 | 100 | 22 | 1 ~90 | - 40 ~ 40 | - 35-80 | ||

| 20 ~ 30 | 750 | 50 | 6 | 1 ~80 | - 10 ~ 30 | - 35-80 | ||

| 30 ~ 35 | 650 | 35 | 4 | 1 ~ 70 | - 5-30 | - 10 ~ 80 | ||

| 35 ~ 40 | 600 | 25 | 2 | 1 ~65 | 1 ~ 60 | 0 ~80 | ||

| 18 ~ 25 m | 1 ~ 5 | 1350 | 130 | 22 | 1 ~ 100 | - 60 ~ 60 | - 40 ~ 90 | |

| 5 ~ 10 | 1150 | 120 | 28 | 1 ku95 | - 50 ~ 50 | - 40 ~ 85 | ||

| 10 ~ 15 | 1000 | 100 | 20 | 1 ku95 | - 40 ~ 40 | - 30 ~ 80 | ||

| 15 ~ 20 | 850 | 85 | 16 | 1 ku85 | - 30 ~ 40 | - 30 ~ 80 | ||

| 20 ~ 25 | 750 | 35 | 3 | 1 ~80 | 1 ~ 60 | 0 ~ 70 | ||

Uma ijubane lingaphezu kuka-20m/min, sincoma ukuthi usebenzise ama-ball bearings ukuze usekele ibhande endleleni ebuyayo.

Kungakhathaliseki ukuthi idizayini yejubane, injini yokushayela kufanele isebenzise idivayisi yokunciphisa isivinini, futhi iqalise esimweni sejubane eliphansi.

Sincoma i-value RP njengebanga elingcono kakhulu.Isikhala esakhiweni sangempela kufanele sibe ngaphansi kwevelu engu-RP.Ukuze uthole isikhala phakathi kwamarola ezindlela ezibuyayo, ungabheka ithebula elingenhla.

I-Value SAG iyisilinganiso esiphezulu esifanele;ukunwebeka kwebhande kufanele kulawulwe ngaphakathi kobubanzi bevelu ye-SAG.

Inani LE ubude obukhulayo be-sag ngemva kokukhipha ubude bebhande ngokombono.