Ukuguqulwa kwamayunithi

| IsiNgisi (USA) Unit X | Phindaphinda nge | = Iyunithi yemethrikhi | X Phinda nge | = Iyunithi yesiNgisi (USA). | ||

| Isilinganiso Somugqa | in | 25.40 | mm | 0.0394 | in | Isilinganiso Somugqa |

| in | 0.0254 | m | 39.37 | in | ||

| ft | 304.8 | mm | 0.0033 | ft | ||

| ft | 0.3048 | m | 3.281 | ft | ||

| Isilinganiso Esiyisikwele | kwe2 | 645.2 | mm2 | 0.00155 | kwe2 | Isilinganiso Esiyisikwele |

| kwe2 | 0.000645 | m2 | 1550.0 | kwe2 | ||

| ft2 | 92.903 | mm2 | 0.00001 | ft2 | ||

| ft2 | 0.0929 | m2 | 10.764 | ft2 | ||

| Isilinganiso seCubic | ft3 | 0.0283 | m3 | 35.31 | ft3 | Isilinganiso seCubic |

| ft3 | 28.32 | L | 0.0353 | ft3 | ||

| Isivinini Sezinga | ft/s | 18.29 | m/min | 0.0547 | ft/s | Isivinini Sezinga |

| ft / min | 0.3048 | m/min | 3.281 | ft / min | ||

| I-Avoirdupois Isisindo | lb | 0.4536 | kg | 2.205 | lb | I-Avoirdupois Isisindo |

| lb/ft3 | 16.02 | kg / m3 | 0.0624 | lb/ft3 | ||

| Ukuthwala Amandla | lb | 0.4536 | kg | 2.205 | lb | Ukuthwala Amandla |

| lb | 4.448 | I-Newton (N) | 0.225 | lb | ||

| kg | 9.807 | I-Newton (N) | 0.102 | kg | ||

| lb/ft | 1.488 | kg / m | 0.672 | lb/ft | ||

| lb/ft | 14.59 | N/m | 0.0685 | lb/ft | ||

| kg - m | 9.807 | N/m | 0.102 | kg - m | ||

| Torque | kwe -lb | 11.52 | kg - mm | 0.0868 | kwe -lb | Torque |

| kwe -lb | 0.113 | N - m | 8.85 | kwe -lb | ||

| kg - mm | 9.81 | N - mm | 0.102 | kg - mm | ||

| Zungezisa Inertia | kwe4 | 416.231 | mm4 | 0.0000024 | kwe4 | Zungezisa Inertia |

| kwe4 | 41.62 | cm4 | 0.024 | kwe4 | ||

| Ingcindezi/Ingcindezi | lb/ku2 | 0.0007 | kg / mm2 | 1422 | lb/ku2 | Ingcindezi / Ingcindezi |

| lb/ku2 | 0.0703 | kg / cm2 | 14.22 | lb/ku2 | ||

| lb/ku2 | 0.00689 | N/mm2 | 145.0 | lb/ku2 | ||

| lb/ku2 | 0.689 | N/cm2 | 1.450 | lb/ku2 | ||

| lb/ft2 | 4.882 | kg / m2 | 0.205 | lb/ft2 | ||

| lb/ft2 | 47.88 | N/m2 | 0.0209 | lb/ft2 | ||

| Amandla | HP | 745.7 | watt | 0.00134 | HP | Amandla |

| ft - lb / min | 0.0226 | watt | 44.25 | ft - lb / min | ||

| Izinga lokushisa | °F | TC = ( °F - 32) / 1.8 | Izinga lokushisa | |||

Uphawu lwe-BDEF

| Uphawu | Iyunithi | |

| BS | I-Conveyor Belt Tensile Amandla | Kg/M |

| BW | Ububanzi Bebhande | M |

C Incazelo Yophawu

| Uphawu | Iyunithi | |

| Ca | Bheka Ithebula FC | ---- |

| Cb | Bheka Ithebula FC | ---- |

D Incazelo Yophawu

| Uphawu | Iyunithi | |

| I-DS | I-Shaft Deflection Ratio | mm |

E Incazelo Yophawu

| Uphawu | Iyunithi | |

| E | Izinga lokwelulwa kwe-Shaft | I-Gpa |

F Incazelo Yophawu

| Uphawu | Iyunithi | |

| FC | I-Friction Coefficient Phakathi Kwe-Belt Edge kanye Ne-Hold Down Strip | ---- |

| I-FBP | I-Friction Coefficient Phakathi Komkhiqizo We-Carry ne-Belt Surface | ---- |

| I-FBW | I-Friction Coefficient Yokusekela Ibhande | ---- |

| FA | I-Coefficient Ichitshiyelwe | ---- |

| FS | I-Tensile Strength Coefficient Ichitshiyelwe | ---- |

| FT | I-Conveyor Belt Temperature Coefficient Ichitshiyelwe | --- |

Uphawu lwe-HILM

| Uphawu | Iyunithi | |

| H | I-Elevation Conveyor incline altitude. | m |

| HP | Amandla amahhashi | HP |

I Symbol Definition

| Uphawu | Iyunithi | |

| I | Isikhathi se-Inertia | mm4 |

L Incazelo Yophawu

| Uphawu | Iyunithi | |

| L | Ibanga Lokudlulisa (Iphoyinti Eliphakathi Kusuka ku-Drive Shaft ukuya ku-Idler Shaft) | M |

| LR | Buyela Indlela Eqondile Yokugijima Kwesigaba | M |

| LP | I-Carry Way Straight Run Ubude besigaba | M |

Incazelo yophawu lwe-M

| Uphawu | Iyunithi | |

| M | I-Spiral Conveyor Layer Level | ---- |

| MHP | I-Motor Horsepower | HP |

Uphawu lwe-PRS

| Uphawu | Iyunithi | |

| PP | Umkhiqizo Onqwabelene Wesilinganiso Sendawo Iphesenti Le-Carry Way | ---- |

R Symbol Incazelo

| Uphawu | Iyunithi | |

| R | I-Sprocket Radius | mm |

| RO | Ngaphandle kweRadius | mm |

| rpm | Revolutions Ngomzuzu | rpm |

S Symbol Incazelo

| Uphawu | Iyunithi | |

| SB | Isikhawu Phakathi Kwe-Bearing | mm |

| SL | I-Shaft Total Loading | Kg |

| SW | Isisindo somphini | Kg/M |

Uphawu lwe-TVW

| Uphawu | Iyunithi | |

| TA | I-Conveyor Belt Unit Ingcindezi Evumelekile | Kg/M |

| TB | I-Conveyor Belt Unit Theory Tension | Kg/M |

| TL | I-Conveyor Belt Unit Catenary's Sag tension. | Kg/M |

| TN | Ukushuba Kwesigaba | kg/M |

| TS | Torque | Kg.mm |

| TW | I-Conveyor Belt Unit Total Tension | Kg/M |

| I-TWS | Uhlobo Olukhethekile Lweyunithi Yebhande Le-Conveyor Total Tension | Kg/M |

V Incazelo Yophawu

| Uphawu | Iyunithi | |

| V | Isivinini Sokudlulisa | M/min |

| VS | Theory Speed | M/min |

W Incazelo Yophawu

| Uphawu | Iyunithi | |

| WB | I-Conveyor Belt Unit Weight | Kg/M2 |

| Wf | Ukucindezeleka Kwe-Conveyance Friction Enqwabelene | Kg/M2 |

| WP | I-Conveyor Belt Carry Product Unit Isisindo |

|

Pusher Futhi Bidirectional

Kumduduzi noma umthumeli we-bidirectional, ukungezwani kwebhande kuzoba phezulu kune-conveyor evamile evundlile;ngakho-ke, ama-shafts emaphethelweni amabili ayadingeka ukuze athathwe njengama-drive shafts futhi afakwe ekubalweni.Sekukonke, cishe izikhathi ezi-2.2 zesici sokuhlangenwe nakho ukuze uthole ukungezwani kwebhande okuphelele.

IFOMU: TWS = 2.2 TW = 2.2 TB X FA

I-TWS kule yunithi isho ukubala okushubile kwesidlulisi se-bidirectional noma pusher.

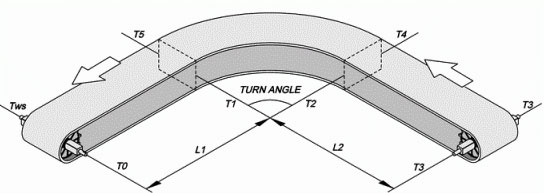

Ukuguqula Ukubala

Isibalo se-tension TWS yesidluliseli esiphendukayo ukubala ukushuba okuqoqiwe.Ngakho-ke, ukungezwani kuzo zonke izingxenye zokuphatha kuzothinta inani lokushuba okuphelele.Lokho kusho ukuthi, ukungezwani okuphelele kunqwabelana kusukela ekuqaleni kwesigaba sokushayela ngendlela yokubuyisela, endleleni ebuyela endaweni engenzi lutho, bese kudlulela esigabeni esithwalayo siye esigabeni sokushayela.

Iphuzu lokuklama kule yunithi yi-T0 engaphansi kwe-drive shaft.Inani lika-T0 lilingana noziro;sibala zonke izigaba kusuka ku-T0.Isibonelo, isigaba sokuqala esiqondile endleleni yokubuyisela sisuka ku-T0 siye ku-T1, futhi lokho kusho ukungezwani okuqoqiwe kwe-T1.

I-T2 ingcindezi enqwabelene yesimo sokujika endleleni yokubuya;kwelinye igama, ukungezwani okuqoqiwe kwe-T0, T1 kanye ne-T2.Sicela ngokwalo mfanekiso ongenhla futhi uthole ukungezwani okunqwabelene kwezigaba zakamuva.

IFOMU: TWS = ( T6 )

Ukushuba okuphelele kwesigaba sokushayela endleleni yokuthwala.

I-TWS kule yunithi isho ukubala kokuqina kwesidluliseli esiphendukayo.

IFOMU: T0 = 0

T1 = WB + FBW X LR X WB

Ukuqina kwe-catenary sag endaweni yokushayela.

IFOMU: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X WB

Ukushuba kwesigaba sokujika endleleni yokubuyisela.

Ukuze uthole inani elingu-Ca ne-Cb, sicela ubheke kuThebula Fc.

T2 = ( Ca X T2-1 ) + ( Cb X FBW X RO ) X WB

TN = ( Ca X T1 ) + ( Cb X FBW X RO ) X WB

IFOMU: TN = TN-1 + FBW X LR X WB

Ukushuba kwesigaba esiqondile endleleni yokubuya.

T3 = T3-1 + FBW X LR X WB

T3 = T2 + FBW X LR X WB

IFOMU: TN = TN-1 + FBW X LP X ( WB + WP )

Ukushuba kwesigaba esiqondile endleleni yokuthwala.

T4 = T4-1 + FBW X LP X ( WB + WP )

T4 = T3 + FBW X LP X ( WB + WP )

IFOMU: TN = ( Ca X TN-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

Ukushuba kwesigaba sokuphenduka endleleni yokuthwala.

Ukuze uthole inani elingu-Ca ne-Cb, sicela ubheke kuThebula Fc.

T5 = ( Ca X T5-1 ) + ( Cb X FBW X RO ) X ( WB + WP )

T5 = ( Ca X T4 ) + ( Cb X FBW X RO ) X ( WB + WP )

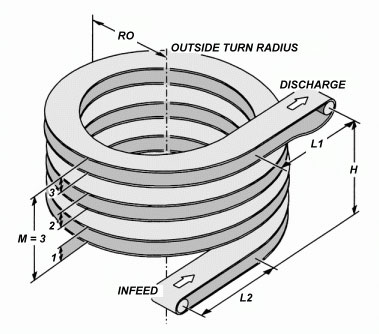

I-Spiral Conveyor

IFOMU: TWS = TB × FA

I-TWS kule yunithi isho ukubala kokuqina kwe-spiral conveyor.

IFOMU: I-TB = [ 2 × RO × M + ( L1 + L2 ) ] ( WP + 2WB ) × FBW + ( WP × H )

IFOMU: TA = BS × FS × FT

Sicela ubhekisele kuThebula FT kanye neThebula FS.

Isibonelo Esisebenzayo

Ukuqhathaniswa kwe-TA ne-TB, nezinye izibalo ezihlobene nazo ziyefana nezinye izinhlobo zabathumeli.Kunemikhawulo ethile kanye nemithethonqubo mayelana nokuklama nokwakhiwa kwe-spiral conveyor.Ngakho-ke, ngenkathi usebenzisa i-HONGSBELT amabhande asongezelayo noma ajikisa amabhande ohlelweni lokuthutha oluvunguzayo, sincoma ukuthi ubheke ibhukwana le-HONGSBELT Engineering futhi uxhumane nomnyango wethu wesevisi yezobuchwepheshe ukuze uthole imininingwane eyengeziwe nemininingwane.

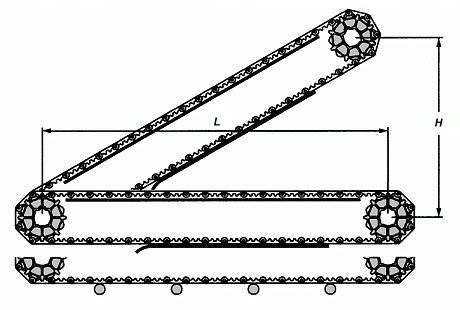

I-Unit Tension

IFOMU: TB = [ ( WP + 2WB ) X FBW ] XL + ( WP XH )

Uma imikhiqizo ephethe inesici sokunqwabelana, amandla okungqubuzana i-Wf anyuka ngesikhathi sokunqwabelana kokuthutha kufanele asetshenziswe esibalweni.

IFOMU: TB = [ ( WP + 2WB ) X FBW + Wf ] XL + ( WP XH )

IFOMU: Wf = WP X FBP X PP

I-Tension Evumelekile

Ngenxa yezinto ezihlukene zebhande linamandla ahlukene aqinile azothinteka ngokuhlukahluka kwezinga lokushisa.Ngakho-ke, ukubalwa kweyunithi ye-tension evumelekile ye-TA kungasetshenziswa ukuze kuqhathaniswe nengqikithi ye-TW yebhande.Lo mphumela wokubala uzokusiza ukuthi wenze ukukhetha okufanele kokukhetha ibhande futhi uhambisane nezidingo zomthumeli.Sicela ubhekisele kuThebula FS kanye neThebula Ts kumenyu engakwesokunxele.

IFOMU: TA = BS X FS X FT

BS = Amandla Okuqina Kwebhande LeConveyor ( Kg / M )

I-FS ne-FT Bhekisela kuThebula FS kanye neThebula FT

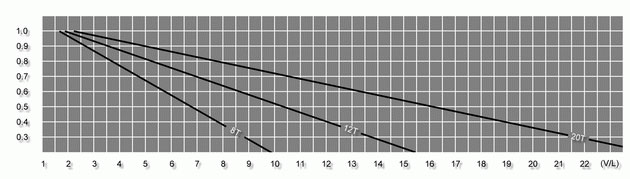

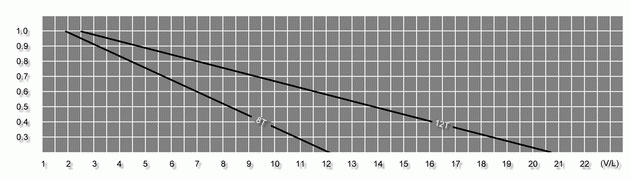

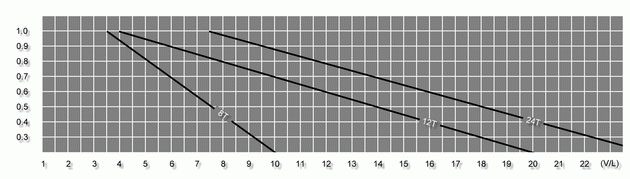

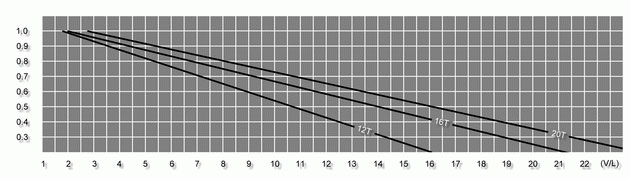

Ithebula Fs

Uchungechunge HS-100

Uchungechunge HS-200

Uchungechunge HS-300

Uchungechunge HS-400

Uchungechunge HS-500

Ithebula Ts

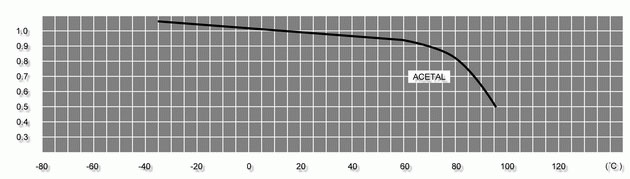

I-Acetal

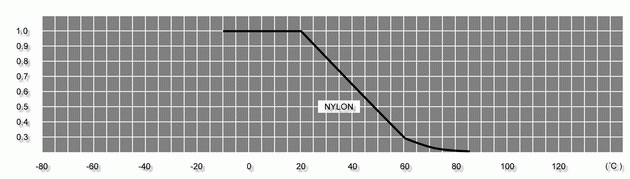

Inayiloni

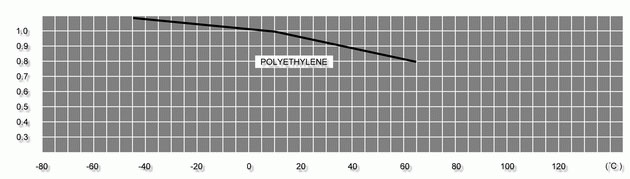

I-polyethylene

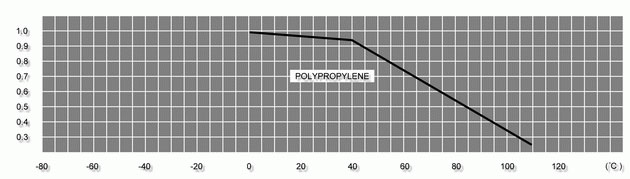

I-Polypropylene

Ukukhetha Shaft

IFOMU: SL = ( TW + SW ) ?BW

I-Driven / Idler Shaft Weight Table - SW

| Ubukhulu beShaft | Isisindo somphini (Kg/M) | |||

| Insimbi Yekhabhoni | Insimbi engagqwali | I-aluminium Alloy | ||

| Isikwele shaft | 38mm | 11.33 | 11.48 | 3.94 |

| 50mm | 19.62 | 19.87 | 6.82 | |

| I-Round Shaft | 30mm?/FONT> | 5.54 | 5.62 | 1.93 |

| 45mm?/FONT> | 12.48 | 12.64 | 4.34 | |

Ukuchezuka kweDrayivu / Idler Shaft - DS

Ngaphandle Ukuzala Okuphakathi

IFOMU :

I-DS = 5 ?10-4 ( SL ?SB3 / E ?/FONT> I )

With Intermediate Bearing

IFOMU :

I-DS = 1 ?10-4 ( SL ?SB3 / E ?I )

Ukunwebeka kwe-Drive Shaft - E

| Iyunithi: Kg/mm2 | |||

| Okubalulekile | Insimbi engagqwali | Insimbi Yekhabhoni | I-aluminium Alloy |

| Shayela Shaft Elastic Rate | 19700 | 21100 | 7000 |

I-Iertia Moment - I

| I-Bore diameter ye-drive sprocket | Umzuzu we-inertia we-shaft ( mm4 ) | |

| Isikwele Shaft | 38mm | 174817 |

| 50mm | 1352750 | |

| I-Round Shaft | 30mm?/FONT> | 40791 |

| 45mm?/FONT> | 326741 | |

Drive Shaft Torque Calculation - TS

| IFOMU : | TS = TW ?BW ?R |

Ngenani lokubala elingenhla, sicela uqhathanise nethebula elingezansi ukuze ukhethe umshini wokushayela ongcono kakhulu.Uma i-torque ye-shaft yedrayivu isenamandla kakhulu, i-sprocket encane ingasetshenziswa ukunciphisa i-torque, futhi iphinde yehlise izindleko eziyinhloko ze-shaft nokuthwala.

Ukusebenzisa i-sprocket encane ukuze kulingane i-drive shaft enobubanzi obukhudlwana ukunciphisa i-torque, noma ukusebenzisa i-sprocket enkulu ukulingana ne-shaft yokushayela enobubanzi obuncane ukuze kukhuliswe i-torque.

I-Torque Factor ephezulu ye-Drive Shaft

| Torque | Okubalulekile | Ububanzi bejenali (mm) | ||||||

| 50 | 45 | 40 | 35 | 30 | 25 | 20 | ||

| Kg-mm x 1000 | Insimbi engagqwali | 180 | 135 | 90 | 68 | 45 | 28 | 12 |

| Insimbi Yekhabhoni | 127 | 85 | 58 | 45 | 28 | 17 | 10 | |

| I-aluminium Alloy | -- | -- | -- | 28 | 17 | 12 | 5 | |

Amandla amahhashi

Uma i-drive motor ikhethelwa i-gear reducer motor, isilinganiso samandla amahhashi kufanele sibe sikhulu kunemikhiqizo ephetheyo kanye namandla anamandla aphelele akhiqizwayo ngesikhathi sokusebenza kwebhande.

Amandla Ehhashi (HP)

| IFOMU : | = 2.2 × 10-4 × TW × BW × V |

| = 2.2 × 10-4 ( TS × V / R ) | |

| = Watts × 0.00134 |

Ama-Watts

| IFOMU : | = ( TW × BW × V ) / ( 6.12 × R ) |

| = ( TS × V ) / ( 6.12 × R ) | |

| = HP × 745.7 |

Ithebula FC

| Impahla Yesitimela | Izinga lokushisa | FC | ||

| Ibhande Lempahla | Yomile | Imanzi | ||

| I-HDPE / UHMW | -10°C ~ 80°C | PP | 0.10 | 0.10 |

| I-PE | 0.30 | 0.20 | ||

| I-Actel | 0.10 | 0.10 | ||

| Inayiloni | 0.35 | 0.25 | ||

| I-Acetal | -10°C ~ 100°C | PP | 0.10 | 0.10 |

| I-PE | 0.10 | 0.10 | ||

| I-Actel | 0.10 | 0.10 | ||

| Inayiloni | 0.20 | 0.20 | ||

Sicela uqhathanise impahla yesitimela nebhande le-conveyor nenqubo yokuthutha endaweni eyomile noma emanzi ukuze uthole i-velue FC.

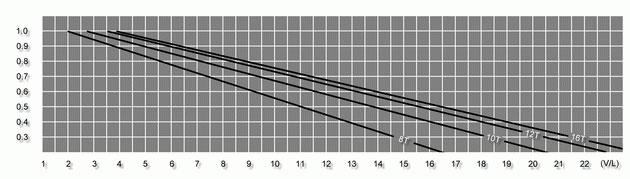

Ca, Inani le-Cb

| I-Conveyor Belt Turning Angle | I-Friction Coefficient Phakathi Kwe-Conveyor Belt Edge & Rail Strip | |||||

| FC ≤ 0.15 | I-FC ≤ 0.2 | I-FC ≤ 0.3 | ||||

| Ca | Cb | Ca | Cb | Ca | Cb | |

| ≥ 15 ° | 1.04 | 0.023 | 1.05 | 0.021 | 1.00 | 0.023 |

| ≥30 ° | 1.08 | 0.044 | 1.11 | 0.046 | 1.17 | 0.048 |

| ≥ 45 ° | 1.13 | 0.073 | 1.17 | 0.071 | 1.27 | 0.075 |

| ≥ 60 ° | 1.17 | 0.094 | 1.23 | 0.096 | 1.37 | 0.10 |

| ≥ 90 ° | 1.27 | 0.15 | 1.37 | 0.15 | 1.6 | 0.17 |

| ≥ 180 ° | 1.6 | 0.33 | 1.88 | 0.37 | 2.57 | 0.44 |

Ngemva kokuthola inani le-FC ku-Table FC, sicela uyiqhathanise ne-engeli egobile yesidluliseli, futhi ungathola inani elingu-Ca kanye nenani elingu-Cb.