Igebe Elintantayo

Lapho uthatha ibhande lokudlulisa ukunyakaza okuphendukayo.ingxenye ye-arc ye-conveyor izohlangana ne-conveyor eqondile futhi iziphetho zombili zesigaba se-arc kufanele ziqondiswe ku-straight, bese umthumeli uzosebenza kahle.

Irediyasi yangaphakathi idinga okungenani izikhathi ezingu-2.2 ububanzi bebhande lokuthutha .

I-STL1 ≧ 1.5 XW noma i-STL1 ≧ 1000mm

Ukuphenduka okukodwa akukhawuli ku-90°;kufanele ithobele umkhawulo wokujika irediyasi futhi yenze umklamo ukusuka ku-15°, 30°, 45°, 60°, 75°, 90°,.... kuya ku-360°.

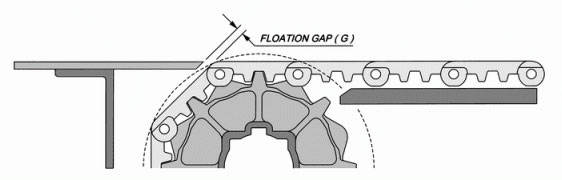

Ithebula Lereferensi Yesikhala Esintantayo (G)

| iyunithi: mm | ||||

| Uchungechunge | Ukujiya Kwebhande | I-Sprocket Diameter (PD) | Inombolo Yamazinyo | Igebe Elintantayo ( G ) |

| 100 | 16 | 133 | 8 | 5.6 |

| 164 | 10 | 4.5 | ||

| 196 | 12 | 4.0 | ||

| 260 | 16 | 3.0 | ||

| 200 | 10 | 64 | 8 | 2.6 |

| 98 | 12 | 1.7 | ||

| 163 | 20 | 1 | ||

| 300 | 15 | 120 | 8 | 4.3 |

| 185 | 12 | 3.3 | ||

| 400 | 7 | 26 | 8 | 1 |

| 38.5 | 12 | 0.3 | ||

| 76.5 | 24 | 0 | ||

| 500 | 13 | 93 | 12 | 1.3 |

| 190 | 24 | 0.5 | ||

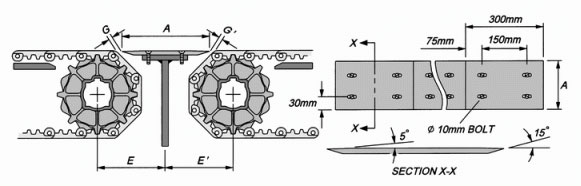

Ipuleti Elifile

Sincoma ukuthi usebenzise insimbi yekhabhoni ewugqinsi engaphezu kuka-5mm, insimbi engagqwali noma insimbi eqinile eqinile njll njengomsebenzi wokukhiqiza ipuleti elifile.Kubalulekile ukucabangela igebe ngalinye lesikhundla sokudlulisa, ukwenza imikhiqizo yokulayisha idlule endaweni yokudlulisa kahle.

Sicela ubhekisele ku-Basic Dimension in Design Specification isahluko ukuze uthole inani elingu-C, bese ubhekisela ku-Gebe Elintantayo kulesi sahluko ukuze uthole inani elingu-G, bese usebenzisa ifomula engezansi, umphumela wokubala uzoba ubukhulu bangempela begebe elintantayo.

IFOMU:

E = CX 1.05

A = ( 2 XE ) ( G + G' )

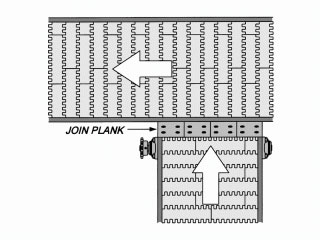

Ukucaciswa Kwedizayini Ye-Side Transfer

Ngokuvamile, isicelo sokudlulisa ama-degree angu-90 sisetshenziswa ngendlela evamile yenqubo yokudlulisa ebalulekile.Sincoma ukuthi usebenzise ibhande lokuvula i-HOMGSBELT;kungakwenza ukuthi usebenzise isikhala ngokuguquguquka.

Uma isikhala sefekthri singesikhulu ngokwanele ukuze kube nerediyasi encane yokujika ye-HOMGSBELT yebhande elijikayo, kuyadingeka ukwamukela umklamo wokudlulisa ohlangothini kuhlaka ukuze uxazulule le nkinga.

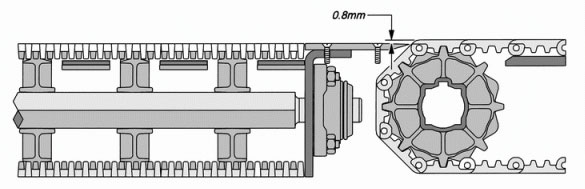

Amarola asizayo

Ngomklamo wendawo yokudlulisa phakathi kwama-conveyor amabili, uma iphansi lemikhiqizo yokulayisha liyisicaba futhi ubude bayo bungaphezu kuka-150mm, ngaphandle kwepuleti elifile, lingakwazi futhi ukusebenzisa i-roller yokudlulisa eyisiza ukusiza ibhande lokudlulisa ukuze uthole ukudluliswa okubushelelezi nokungcono. ukunyakaza ngesikhathi sokusebenza.

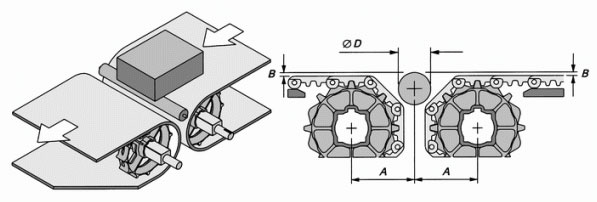

Ukucaciswa Kwedizayini kwama-Axiliary Transfer Rollers ku-Drive / Idler Position

| iyunithi: mm | ||||||

| Uchungechunge | Ubukhulu (Ibhande) | I-Sprocket Dia. | Inombolo Yamazinyo | A (min.) | B (imiz.) | D (ubukhulu) |

| 100 | 16 | 133 | 8 | 85 | 0~1 | 34 |

| 164 | 10 | 100 | 40 | |||

| 196 | 12 | 116 | 50 | |||

| 260 | 16 | 150 | 66 | |||

| 200 | 10 | 64 | 8 | 47 | 20 | |

| 98 | 12 | 63 | 25 | |||

| 163 | 20 | 95 | 40 | |||

| 300 | 15 | 120 | 8 | 88 | 40 | |

| 185 | 12 | 106 | 44 | |||

| 400 | 7 | 26 | 8 | 20 | 10 | |

| 38.5 | 12 | 28 | 15 | |||

| 76.5 | 24 | 53 | 25 | |||

| 500 | 13 | 93 | 12 | 64 | 25 | |

| 190 | 24 | 118 | 40 | |||

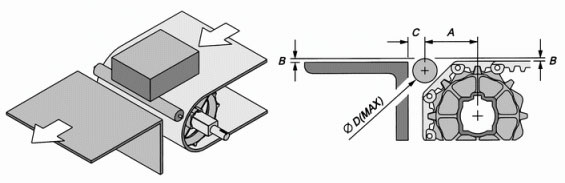

Ukucaciswa Kwedizayini Yezinsimbi Zokudluliswa Kwezisiza Ekudluliselweni Kwenkundla

| Iyunithi: mm | |||||||

| Uchungechunge | Ubukhulu (Ibhande) | I-Sprocket Dia. | Inombolo Yamazinyo | A (min.) | B (imiz.) | C (imizuzu) | D (ubukhulu) |

| 100 | 16 | 133 | 8 | 74 | 0~1 | 23 | 20 |

| 164 | 10 | 92 | 28 | 25 | |||

| 196 | 12 | 106 | 33 | 30 | |||

| 260 | 16 | 138 | 41 | 38 | |||

| 200 | 10 | 64 | 8 | 42 | 18 | 15 | |

| 98 | 12 | 60 | 21 | 18 | |||

| 163 | 20 | 93 | 28 | 25 | |||

| 300 | 15 | 120 | 8 | 76 | 28 | 25 | |

| 185 | 12 | 108 | 30 | 27 | |||

| 400 | 7 | 26 | 8 | 17 | 9 | 6 | |

| 38.5 | 12 | 24 | 12 | 9 | |||

| 76.5 | 24 | 45 | 18 | 15 | |||

| 500 | 13 | 93 | 12 | 56 | 18 | 15 | |

| 190 | 24 | 108 | 28 | 25 | |||

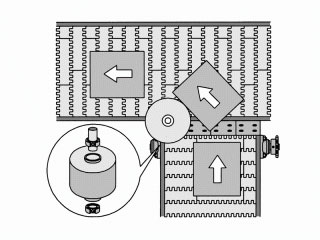

Qondisa idivayisi

Uma amapuleti afile noma amarola okudlulisa ayisizayo esetshenziselwa indawo yokudlulisa yesistimu yokuthutha, umehluko wejubane lomugqa noma amandla we-centrifugal, imikhiqizo izophonswa ngaphandle noma iphambuke endaweni emaphakathi yebhande.Okwamanje, kuyadingeka ukufaka idivayisi yomhlahlandlela ukusiza imikhiqizo idlule endaweni yokujika kahle futhi ngaphakathi kwendawo yokuthutha ephumelelayo.

Ukucaciswa Kwedizayini Yeroli Yomhlahlandlela

Ama-roller omhlahlandlela ngokuvamile enziwe ngezinto zensimbi.Irediyasi yayo eyisiqondiso icishe ibe ngu-1/4 ububanzi obusebenzayo bebhande.Uma imikhiqizo yokulayisha ifunwa ukuze kuthuthukiswe ukungqubuzana, kufanele isebenzise irabha noma impahla ye-PVC ukuze isonge ingaphezulu lamarola angumhlahlandlela.Ifaneleka ngokukhethekile ukulayisha okukhulu noma okusindayo kwemikhiqizo yokuthutha.Ukusebenzisa ama-ball bearings ku-guide roller kungenza i-roller ijikeleze bushelelezi.

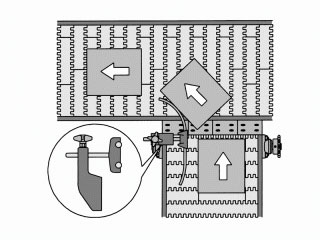

Ukucaciswa Kwedizayini Yesitimela Somhlahlandlela

Iningi lamadivaysi okuqondisa ngokuvamile enziwa ngezinto zepulasitiki ezinokungqubuzana okuphansi, njenge-UHMW, HDPE nokunye.Ingaklanywa ibe yizimo eziningi noma ukubonakala kwezidingo zokufaka.Ama-rails aqondisayo afanele ukulayishwa kosayizi omaphakathi noma omncane wohlelo lokuthutha.Ama-rails omhlahlandlela nawo enziwe ngezinto zepulasitiki ezine-friction ephansi.Abakhiqizi banganikeza ama-rails amaningi omhlahlandlela kuzo zonke izinhlobo zomumo ngezidingo zamakhasimende.

Lapho isistimu yokuthutha ithatha ipuleti elifile noma i-axiliary bear isuka kwesinye isihambisi iye kwesinye nge-engeli engu-90 degree, ukuhlanganisa amarola angumhlahlandlela nama-guide rails kuzokwenza inqubo yokuthutha ibe bushelelezi futhi ibe lula.

Sicela unake ukuthi imikhiqizo izoshaya yini umzila wesitimela wangaphandle ngenxa yamandla aphakathi nendawo lapho ibhande ligijima lifika endaweni yokujika, noma leqe uhla olusebenzayo lokuthwala amabhande futhi kubangele ukuthi imikhiqizo inqwabelane futhi imise umugqa wokukhiqiza.Ngokuvamile, ububanzi obusebenzayo bebhande kufanele bube bukhulu kunobubanzi obukhulu bemikhiqizo yokulayisha.