Hlola kuqala

Hlola ibhande ukuze uthole izimo ezingavamile noma umonakalo ngaphambi kokuqala.

Hlola futhi uqiniseke ukuthi i-catenary sag phansi kwebhande isesimweni esifanele.

Uma isidluliseli sithatha ukulungiswa kwe-tension, kuhlole futhi uqinisekise ukuthi ukushuba kwebhande akuqini ngokweqile.Ungeqi amandla ibhande elingakwazi ukubekezelela, ngaphandle kwe-conveyor yohlobo oluphushiwe.

Hlola wonke ama-roller asekelayo futhi uqiniseke ukuthi asesimweni esihle sokuzungezisa.

Hlola i-drive/idler sprocket ukuze uthole umonakalo omkhulu wokuguga

Hlola indawo yokuhlangana phakathi kwama-sprockets nebhande ukuze ukhiphe zonke izinto ebezinamathele ngaphakathi.

Hlola zonke izindwangu ezigqokwayo futhi ubambe ojantshi ukuze uthole noma yimuphi umonakalo ongajwayelekile noma owedlulele.

Hlola kokubili ama-drive kanye namashafti angasebenzi, futhi uqiniseke ukuthi ahlanganiswe nebhande lokudlulisa.

Hlola zonke izikhundla obekudingeka ukuze zigcotshwe futhi uqiniseke ukuthi zisesimweni esijwayelekile.

Hlola zonke izindawo obekudingeka ukuze kuhlanzwe isistimu yokuthutha.

Ukuhlanza Ukubaluleka

Lapho uhlanza ibhande, kudingekile ukugwema ukusebenzisa okokuhlanza okuqukethe izithako ezibolayo.

Nakuba kuphumelela futhi kuwusizo ukusebenzisa okokuhlanza ukugeza ukungcola;kodwa-ke, kungase kube nomthelela ezintweni zepulasitiki zebhande futhi kufinyeze isikhathi sokuphila sebhande.

Imikhiqizo ye-serial yebhande le-HONGSBELT iklanywe ngokuyisisekelo ngezici zokuhlanza nokukhipha amanzi kalula;ngakho-ke, kuyindlela efanele kakhulu yokuhlanza amabhande ngamanzi anomfutho ophezulu noma umoya ocindezelweyo.

Ngaphandle kwalokho, kuyadingeka ukuhlanza ukungcola nezinye izinto zokuphahlazeka kusuka phansi noma ingxenye yangaphakathi yesithumeli.Sicela uqiniseke ukuthi umshini uvala ugesi ukuze ugweme noma yikuphi ukulimala okungenzeka.Kwezinye izinhlelo zokusebenza zokukhiqiza ukudla, kukhona ufulawa omuncu, isiraphu noma ezinye izinto eziyinsalela eziwela kusistimu yokuthutha futhi okuholela ekungcoleni komthumeli.

Okunye ukungcola okunjengothuli, amatshe, isihlabathi noma i-cullet kungase futhi kuthinte isistimu yokuthutha ukuze ihlangabezane nezinkinga ezinkulu.Ngakho-ke, ukuhlanza okujwayelekile noma ngezikhathi ezithile zohlelo lokuthutha kuwumsebenzi obalulekile wokugcina okokusebenza kusesimweni esijwayelekile.

Isondlo

Ukuhlola okujwayelekile noma okwenziwa ngezikhathi ezithile kwe-conveyor ngokuyinhloko ukuvimbela izinkinga ezithile ezingajwayelekile, futhi kukusize ukuba unakekele isithumeli ngaphambi kokuba kuvele izimo zokuhluleka.Ngokuvamile, abasebenzisi bangabheka isimo sokuguga ngokuhlola okubonakalayo, futhi banqume ukuthi kudingekile yini ukuqhubeka nanoma yikuphi ukulungiswa noma ukushintshwa noma cha.Sicela ubheke Ukudutshulwa Kwenkinga kumenyu engakwesokunxele ukuze uthole ukunakekelwa kanye nenjongo yokufaka esikhundleni.

Ibhande lokuthutha linesikhathi esithile sokuphila ngaphansi kokusetshenziswa okuvamile;iwaranti yamabhande okuthutha e-HONGSBELT yizinyanga eziyi-12.Ngemuva kokusetshenziswa isikhathi eside, ibhande lizoguga, liphambukiswe ngenxa yokulayisha ngokweqile, noma kwandiswe isikhala.Kuzo zonke izizathu ezishiwo ngenhla kuzoholela ekuhlanganyeleni okungalungile phakathi kwebhande nama-sprockets.Kudingeka ukulondoloza noma ukufaka esikhundleni sebhande ngaleso sikhathi.

Ngesikhathi sokusebenza kwe-conveyor, ibhande le-conveyor, ama-wearstrip nama-sprockets azogqoka ngokuzenzakalelayo.Uma kukhona noma yisiphi isimo sokuhuzuka kwebhande lokuhambisa, sincoma ukuthi esikhundleni salokho kufakwe izisekeli zebhande elisha, ukuze kugcinwe isisetshenziswa esithwalayo sisebenza ezimeni ezijwayelekile.

Ngokuvamile, lapho isidluliseli sidinga ukumiselela ibhande elisha, ama-wearstrip nama-sprocket atuswa ngokuqinile ukuthi avuselele ngesikhathi esifanayo.Uma singakunaki noma yikuphi, kungase kukhuphule ukulimala kwebhande futhi kunciphise ubude bempilo yebhande nezinye izinto.

Ikakhulukazi ibhande le-HONGSBELT lokuthutha lidinga kuphela ukufaka amamojula amasha esikhundleni somonakalo, alidingi ukushintsha lonke ibhande.Vele uqaqa ingxenye eyonakele yebhande, bese ufaka amamojula amasha, bese umthumeli angabuyela ekusebenzeni kalula.

Ukuphepha Nesexwayiso

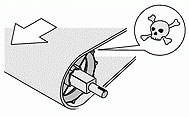

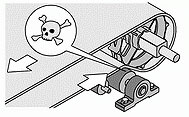

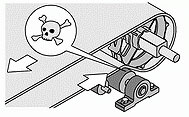

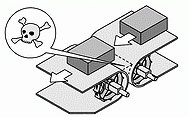

Uma ibhande lokuthutha lisebenza, kunezindawo ezimbalwa eziyingozi okumele abaqhubi, abasebenzisi nabasebenzi bezokulungisa banake.Ikakhulukazi ingxenye eqhutshwayo yesihambisi, ingase ibambene noma ilimaze umzimba womuntu;ngakho-ke, wonke umuntu kufanele abe nokuqeqeshwa okufanele kanye nemfundo ye-conveyor esebenza kusenesikhathi.Kuyadingeka futhi ukulebula izexwayiso eziyingozi kanye nezinkomba endaweni yengozi ngombala okhethekile noma izimpawu eziyisixwayiso, ukuze kugwenywe ingozi yengozi ngesikhathi sokusebenza kwesithuthi.

Inkomba Yendawo Eyingozi

▼ Indawo eshayela i-sprocket ehlanganiswe nebhande.

▼ Isikhundla esibuyisela indlela yokuxhumana ye-roller nebhande.

▼ Indawo i-Idler sprocket ehlanganiswe nebhande.

▼ Igebe lesikhundla sokudlulisa phakathi kwama-conveyors.

▼ Isikhawu phakathi kwamaconveyor anerola yokudlulisa.

▼ Isikhawu phakathi kwamaconveyor anepuleti elifile.

▼ Isikhundla ibhande elithintene nokuvimbela ohlangothini.

▼ Isikhundla se-backbend Radius endleleni yokuthwala.

▼ Isikhundla se-backbend radius ngendlela yokubuyisela.

▼ Indawo lapho unqenqema lwebhande luxhunywe khona nohlaka.

Ukuphuka Kwebhande

| Isizathu | Indlela Yokuxazulula |

| Ukwehluleka kwamandla ngesikhathi sokuphatha inani elikhulu lemikhiqizo, ngenkathi amandla ebuya, isidluliseli sizoqala ngokushesha ngokulayisha okugcwele, ingcindezi eqinile yokudonsa kwengcindezi kubangela ukugqashuka kwebhande lokuthutha. | Khipha imikhiqizo yokuthwala ebhandeni bese ushintsha amamojula amasha endaweni ephukile, bese uqala kabusha uhlelo. |

| Izithiyo zisungulwa phakathi kwefreyimu ye-conveyor nebhande, njengesikulufu esixegayo noma izikhala zemicu yokugqokwa esekelayo.Lokhu kungase kubangele isimo sokulayisha ngokweqile futhi kulimaze ibhande lokuthutha. | Susa izithiyo futhi ulungise igebe lokuxhumana phakathi kohlaka lokuthutha nebhande. |

| Isikhundla se-backbend radius sibhajwe izinto zangaphandle esikhaleni esiphakathi kwamamojula amabhande epulasitiki. | Sicela ubhekisele ku-Backbend Radius in Incline noma Yenqaba Isahluko Somklamo. |

| Ukuchezuka kokugijima kwebhande kubangela ukuvinjelwa kokulimaza, okufana nomthelela ongavamile noma ukuthintana nezikulufu zokubopha kuhlaka lomshini. | Hlola uhlaka lomshini ngokuphelele , futhi uhlole noma isiphi isimo sokuxega okungavamile , ikakhulukazi kulezo zikulufu zokubopha. |

| Izigxobo ziyawa embotsheni yokukhiya, kuholele izinduku zehinge ziphume onqenqemeni lwebhande lokuthutha futhi ziminyanise uhlaka lwangaphakathi lomzimba womshini. | Shintshanisa amamojula ebhande lokuthutha alimele, izinti zokuhinga nezinduku zokukhiya.futhi uhlole zonke izimo ezingavamile ngokucophelela. |

| I-engeli ye-backbend radius incane kakhulu okuholela ekulimaleni ngenxa yokuvinjwa kokucindezelwa. | Sicela ubhekisele ku-Backbend Radius in Incline noma Yenqaba Isahluko Somklamo |

Ukuhlanganyela Okubi

Gqoka

| Isizathu | Indlela Yokuxazulula |

| Kukhona ukuchezuka kwe-engeli yozimele wesihambisi. | Lungisa ukwakheka komthumeli. |

| Ama-Wearstrip awafaki ukuhambisana nozimele wesihambisi. | Lungisa ukwakheka komthumeli. |

| Asikho isikhala esifanelekile ebesibekelwe ububanzi bebhande kanye nohlaka oluseceleni lwesidluliseli | Sicela ubhekisele ku-Basic Dimension in Design Specification isahluko. |

| Imvelo yokusebenza kokuthutha inokushintsha okukhulu kwezinga lokushisa ekwandeni nokufinyela kwezinga lokushisa. | Sicela ubhekisele ku-Expansion Coefficient kusahluko sokucaciswa komklamo. |

| I-Center sprocket ayikhiyi ngokunembile endaweni emaphakathi yedrayivu / i-idler shaft ye-conveyor | Hlukanisa i-sprocket kusuka ku-shaft bese usetha kabusha endaweni enembile emaphakathi ye-shaft. |

| Ulayini oqondile ophakathi nendawo webhande lokuthutha alihlangani kahle ne-sprocket emaphakathi. | Lungisa ukwakheka kwesidluliseli ukuze kubandakanyeke kahle. |

Umsindo Ongajwayelekile

| Isizathu | Indlela Yokuxazulula |

| Ukuguqulwa kwesakhiwo sokuthutha kubangela ukuthi ihabhu le-sprocket lingakwazi ukusebenzelana okufanele nesikhala se-taper ngaphansi kobuso bebhande lokuthutha. | Lungisa idrayivu / i-Idler shaft ngo-90 degree kuhlaka lokudlulisa. |

| Ebhandeni elisha sha lokuthutha, kukhona ama-burrs asele kumamojula epulasitiki ngemuva kokwakhiwa komjovo. | Lokhu ngeke kube nomthelela ekusebenzeni kwebhande, ama-burrs azonyamalala ngemuva kokusebenza isikhathi eside. |

| Ama-Sprockets kanye nebhande lokuthutha kuwukunqamuka okukhulu noma ibhande ngokwalo liyancipha ngokweqile. | Shintshanisa ama-sprocket amasha noma ibhande elisha lokuthutha. |

| Ukuma okusekelayo kwebhande lokuthutha akusebenzisi okokusebenza kwe-coefficient ephansi ukuze kukhiqizwe izikhala ezisekelayo. | Shintshanisa izikhala ezisekelayo ezazenziwe ngezinto zepulasitiki nge-coefficient ephansi yokungqubuzana. |

| Uhlaka lwe-conveyor selukhululiwe. | Hlola lonke uhlaka lwe-conveyor bese ubophela isikulufu ngasinye sebhawodi . |

| Ezinye izinto ezinamathela esikhaleni esihlangene samamojula zitholakele. | Susa ezinye izinto bese uhlanza ibhande. |

| Ngenxa yokuhlukahluka kwezinga lokushisa, ibhande lokuthutha linoshintsho olukhulu ekwandiseni okushisayo nokufinyela. | Sicela ubhekisele ku-Temperature Rang of Belt Materials bese ukhetha ibhande lokuthutha elifanele ukulisebenzisa ebangeni elithile lokushisa. |

Thuthumela

| Isizathu | Indlela Yokuxazulula |

| Isikhawu esiphakathi kwamarola endlela yokubuyisela sidlulele. | Ukuze ulungise isikhathi esifanele phakathi kwamarola, sicela ubheke Ithebula le-Catenary Sag kusahluko sobude bebhande kanye ne-Tension. |

| Ijika elidlulele le-catenary sag ngendlela ebuyayo lingase libangele i-engeli yokuxhumana phakathi kwendawo ye-catenary sag kanye namarola abuyayo abe makhulu.Lokho kungaholela ekunyakazeni kwebhande, futhi i-idler sprocket ayikwazi ukumunca indlela yokubuya kahle.Ibhande lizosebenza esimweni sokuthuthumela. | Ukuze ulungise isikhathi esifanele phakathi kwamarola, sicela ubheke Ithebula le-Catenary Sag ku-InclLength & Tension chapter. |

| Ukuhlangana okungafanele kwamabhande okugqokwa nokubamba ama-rails kungaba nomthelela ekusebenzeni kwebhande. | Lungisa noma lungisa kabusha izinsimbi zokubamba.Amareyili ekungeneni kwebhande adinga ukucutshungulwa abe ngunxantathu ohlanekezelwe . |

| Kukhona ukwehla ngokweqile ku-engeli yendawo ehlanganyelwe phakathi kwe-drive / idler shaft kanye nendawo yokusekela. | Sicela ubhekisele ku-Basic Dimension in Design Specification isahluko. |

| Irediyasi ye-backbend yebhande ayilandeli umkhawulo werediyasi omncane o umklamo. | Sicela ubhekisele ku-Backbend Radius Ds ku-Incline noma ye-Decline Design isahluko. |

| Ububanzi bendlela yokubuya yama-roller noma ama-wearstrip mancane kakhulu;bekungaphumela ekulimaleni kwemichilo. | Sicela ubheke isahluko se-Return Way Rollers ku-Return Way Support. |

| Indlela ebuya ngayo ukushuba kwebhande ayifani ngokuphelele nokushuba kwendlela yokuthwala yebhande . | Lungisa ukungezwani kahle, kungase futhi kunyuse noma kunciphise ubude bebhande lokudlulisa. |

| Ibhande le-EASECON elijikayo linendawo engaphakathi ngokwedlulele. | Lungisa ukungezwani kwebhande lokudlulisela ngendlela efanele njengoba kushiwo ngenhla, noma shintsha ngokuqondile ama-reils okubamba okokusebenza okuku-coefficient ephansi yokungqubuzana njenge-Teflon noma i-Polyacetal.Kusetshenziswa uketshezi lwensipho noma okokugcoba onqenqemeni lwangaphakathi lwe-reiling down, ama-wearstrip aphezulu kanye nezinga eliphansi nakho kuyatholakala.Le ndlela ingase ibe usizo ekuxazululeni inkinga. |

Izibazi ebusweni

| Isizathu | Indlela Yokuxazulula |

| Ukusika ngokucophelela kwe-blade kushiye izibazi ezijulile endaweni yebhande. | I-sandpaper indawo yebhande ibushelelezi.Uma isakhiwo sebhande sinomonakalo omkhulu, sicela ushintshe indawo eyonakele ngamamojula amasha. |

I-IQF

| Isizathu | Indlela Yokuxazulula |

| Amaphutha okusebenza ekuqaliseni komthumeli wenqubo yomuntu ngamunye eqandisiwe esheshayo, futhi amamojula amabhande abhajwe izinga lokushisa elibandayo elidlulele, kungaholela ekucindezelekeni okunamandla lapho kuqaliswa uhlelo;liphakeme ngokwedlulele kunamandla aqinile ibhande lokuthutha elingabekezelela. | Qinisekisa ukuthi uhlelo luqalisa ngenqubo efanele, bese ushintsha amamojula amasha endaweni ephukile;bese uqala isidluliseli ngokwenqubo efanele.Sicela ubheke Ithempelesha Eliphansi Esahlukweni Sendlela Yokusekela. |

| Ubude bebhande bufushane kakhulu, futhi lizogqashuka ngenxa yokwanda nokuncipha kwe-thermal. | Sicela ubheke I-Expansion Coefficient kuSahluko sokucaciswa komklamo, ukuze ubale ubude bebhande obunembile obudingekayo. |

| Indawo yokuxhumana ebanzi phakathi kwezingubo zokugqoka kanye nebhande lokudlulisa kuzodala ukunqwabelana kweqhwa. | Khetha imichilo emincane yokugqoka ukuze unciphise indawo yokuxhumana, sicela ubheke Ithempelesha Eliphansi Esahlukweni Sendlela Yokusekela. |

| Ukwehluka okukhulu kwezinga lokushisa lokunwetshwa kwe-thermal kanye nokufinyela kuzoholela ekuwohlokeni nasekujikeni kozimele wesidlulisi. | Ngesikhathi sokwenziwa kwesidluliseli esibalulekile, iyunithi yokuxhuma yohlaka olunobude kufanele igcine okungenani ibanga elingu-1.5 M. |