Ukuhlelwa

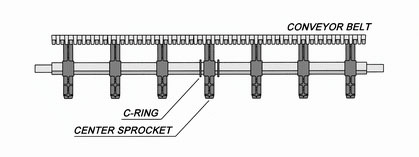

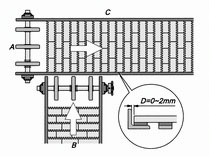

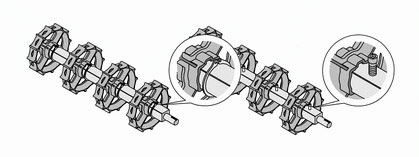

I-sprocket ephakathi kufanele ibekwe endaweni ephakathi nendawo yobubanzi bebhande lokuthutha, ukuze kuqinisekiswe ukuthi isiqondiso sokuthutha sizogcina ukunyakaza okuqondile ngesikhathi sokuhamba kwe-conveyor.I-drive / Idle sprockets kufanele ilungiswe yi-C shape retain rings nhlangothi zombili, ukuqinisekisa ukuthi ama-sprockets akhiyelwe endaweni efanele.Lawa ma-sprockets agcinayo azohlinzeka ngethrekhi ephozithivu yokugcina ibhande lisebenza kahle phakathi kwamafreyimu aseceleni wesithumeli.

Ngaphandle kwe-sprocket ephakathi kufanele ibekwe endaweni ephakathi kwe-shaft, amanye ama-sprocket akudingekile ukuba alungiswe;bavunyelwe ukuba bakhululeke ukuhlanganyela nebhande esimweni sokunwetshwa kokushisa nokunciphisa.Le ndlela yokushayela ingavimbela ukubandakanya okungalungile kwebhande nama-sprockets.

Mayelana nokuhlelwa kwesikhala phakathi kwama-sprockets, sicela ubhekisele ku-Sprocket Spaceing kumenyu engakwesokunxele.

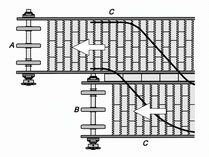

I-Sprocket Arangement of Turning Conveyor Belt

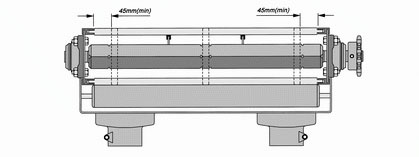

Ngenkathi uhlela ama-sprocket, isikhala ngeke sibe ngaphezu kuka-145mm futhi i-sprocket emaphakathi kufanele ilungiswe ngamaringi okugcina.

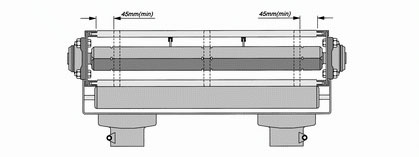

Uma ubude besistimu yokuthutha ingaphansi kuka-4 ububanzi bebhande, isikhala asikho ngaphezu kuka-90mm.Isikhala phakathi kwe-sprocket yangaphandle kanye nonqenqema lwebhande kufanele sibe ngaphezu kwama-45mm.

Mayelana nokuhlelwa kwesikhala phakathi kwama-sprockets, sicela ubhekisele ku-Sprocket Spaceing kumenyu engakwesokunxele.

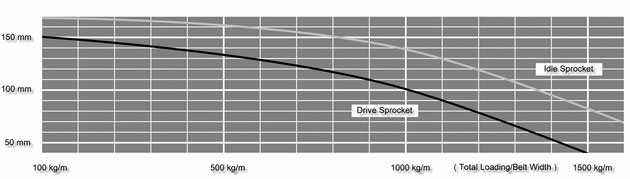

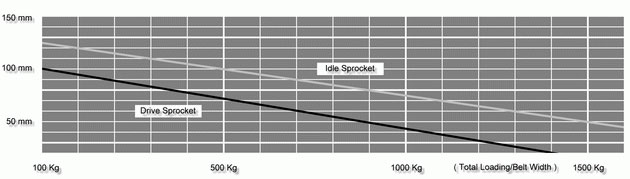

I-Sprocket Spacing Diagram of Series 100

Amanothi

Igrafu engenhla yidatha yesikhala yesikhungo se-sprocket;le datha iwukulinganiselwa futhi iyireferensi kuphela.Sicela ubeke phambili isikhundla sangempela ama-sprocket asebenzisana nebhande ngenkathi aklama futhi ecutshungulwa.

Sicela ubheke idatha yejika bese usetha izikhala ngenkathi ufaka ama-sprocket.Kufanele yabiwe ngokwesilinganiso futhi ibe mancane kunedatha yekhevu.

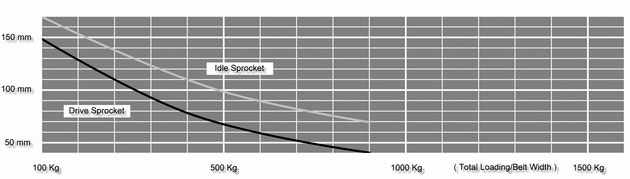

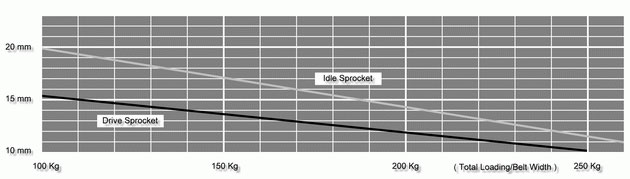

I-Sprocket Spacing Diagram of Series 200

Amanothi

Igrafu engenhla yidatha yesikhala yesikhungo se-sprocket;le datha iwukulinganiselwa futhi iyireferensi kuphela.Sicela ubeke phambili isikhundla sangempela ama-sprocket asebenzisana nebhande ngenkathi aklama futhi ecutshungulwa.

Sicela ubheke idatha yejika bese usetha izikhala ngenkathi ufaka ama-sprocket.Kufanele yabiwe ngokwesilinganiso futhi ibe mancane kunedatha yekhevu.

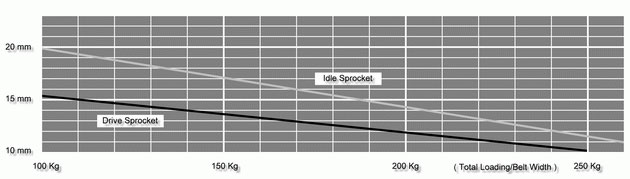

I-Sprocket Spacing Diagram yochungechunge 300

Amanothi

Igrafu engenhla yidatha yesikhala yesikhungo se-sprocket;le datha iwukulinganiselwa futhi iyireferensi kuphela.Sicela ubeke phambili isikhundla sangempela ama-sprocket asebenzisana nebhande ngenkathi aklama futhi ecutshungulwa.

Sicela ubheke idatha yejika bese usetha izikhala ngenkathi ufaka ama-sprocket.Kufanele yabiwe ngokwesilinganiso futhi ibe mancane kunedatha yekhevu.

I-Sprocket Spacing Diagram yochungechunge 400

Amanothi

Igrafu engenhla yidatha yesikhala yesikhungo se-sprocket;le datha iwukulinganiselwa futhi iyireferensi kuphela.Sicela ubeke phambili isikhundla sangempela ama-sprocket asebenzisana nebhande ngenkathi aklama futhi ecutshungulwa.

Sicela ubheke idatha yejika bese usetha izikhala ngenkathi ufaka ama-sprocket.Kufanele yabiwe ngokwesilinganiso futhi ibe mancane kunedatha yekhevu.

I-Sprocket Spacing Diagram yochungechunge 500

Amanothi

Igrafu engenhla yidatha yesikhala yesikhungo se-sprocket;le datha iwukulinganiselwa futhi iyireferensi kuphela.Sicela ubeke phambili isikhundla sangempela ama-sprocket asebenzisana nebhande ngenkathi aklama futhi ecutshungulwa.

Sicela ubheke idatha yejika bese usetha izikhala ngenkathi ufaka ama-sprocket.Kufanele yabiwe ngokwesilinganiso futhi ibe mancane kunedatha yekhevu.

cross & parallel

Ngesikhathi kusetshenziswa amabhande okuthutha ukuze kuxhunywe iziphambano, ukunakekelwa okukhethekile kufanele kuthathwe ngendlela ehleliwe yama-sprockets.

Lapho isidluliseli esingu-B sihlangana nesidluliseli A, i-sprocket yesidluliseli A esiseduze nesidluliseli esingu-B kufanele simiswe.Ngaphandle kwalokho, inani D le-conveyor A (Ithebula 9 ) kufanele lehliswe, futhi isikhala kufanele sengezwe enanini D lohlangothi C. Konke ukubekezelela ukunwetshwa kwesithumeli A kugcinwa kuhlangothi C ukuze uthole umphumela omuhle kakhulu wokuxhuma.

I-Sprocket Arangement for Parallel Connection of Conveyors

Ngesikhathi kusetshenziswa amabhande okuhambisa ukuze kuxhunywe ngokufanayo, kufanele kuqashelwe ngokukhethekile ukulungisa i-sprocket ye-drive yabo bobabili abathumeli ohlangothini oluseduze nomunye umthumeli.Ngevelu engu-D, sicela ubhekisele emfanekisweni oshiwo ngenhla, futhi ugcine isikhala sokubekezelela ukunweba ohlangothini C ukuze uvumele isikhala phakathi kwamafreyimu ama-conveyor amabili sehle siye kumkhawulo ophansi kakhulu lapho izinga lokushisa lishintsha.

I-Idle Sprocket

IsikhungoI-sprocket ye-shaft engenzi lutho kufanele ilungiswe ngamasongo okugcina, ukuqinisekisa ukuthi isiqondiso sokuthutha sizobe siqondile ngaphandle kokutsheka.Inombolo ye-drive sprockets kukhishwe 2 inani lama-sprocket angenalutho.Isikhala kufanele sisatshalaliswe ngokwesilinganiso ku-shaft.Inani lama-sprocket angasebenzi alikwazi ukuba ngaphansi kwezingcezu ezi-3.Sicela ubhekisele ku-Sprocket Spacing kumenyu engakwesokunxele.

I-Idle Sprocket Arangement for Turning Conveyor Belt

Isikhala se-sprocket ku-shaft engenzi lutho ngeke sibe ngaphezu kuka-150mm ngesikhathi sokuklama.Uma isistimu yokuthutha iklanywe ngendlela yokudlulisela kabili, ukuhlelwa kwama-sprocket angasebenzi kufanele kufane nama-sprockets okushayela.Sicela ubhekisele ku-Sprocket Spacing kumenyu engakwesokunxele.

Ukusebenza Kwesikhashana

Ngenkathi umthumeli wempahla esesimweni sokusebenza ngezikhathi ezithile, kuzoba lula ukwenzeka isenzakalo sokugudluzwa kwebhande nhlangothi zombili futhi kubangele ukusebenzelana okungalungile phakathi kwebhande nama-sprockets.Ama-sprockets amahhala azoshintshela ezinhlangothini zombili ze-shaft ngenxa yokuthi awalungiswa ngamaringi okugcina.Uma isimo singalungiswa, sizoba nomthelela ekusebenzeni komthumeli.

I-adaptha eyi-Hexagonal

Ukuze uthole ukuhanjiswa komkhiqizo olula, i-drive/i-shaft engenzi lutho ingasebenzisa i-adaptha eyindilinga esikhundleni sokucutshungulwa kwe-square shaft.Kunconywa ukufaka isicelo endaweni yokusebenza yokulayisha ukukhanya kanye nebhande ububanzi obungaphakathi kuka-450mm.

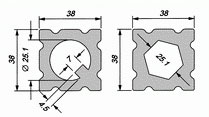

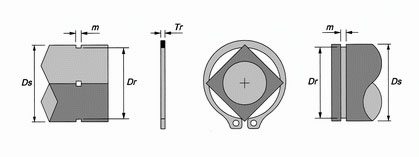

Izindandatho Zokugcina

| DS | Ikhodi | m | Tr | Dr | |

| Isikwele | 38 mm | 52 | 2.2 mm | 2 mm | 47.8 mm |

| 50 mm | 68 | 2.7 mm | 5 mm | 63.5 mm | |

| 64 mm | 90 | 3.2 mm | 3 mm | 84.5 mm | |

| Umjikelezo | ?30 mm | 30 | 1.8 mm | 1.6 mm | 27.9 mm |

| ?45 mm | 45 | 2.0 mm | 1.8 mm | 41.5 mm | |